Home Construction Management Carpentry Terms

Carpentry Terms: A Glossary of Industry Lingo + Detailed Definitions

Learn essential carpentry terms, techniques, and industry jargon in this glossary to enhance your skills and improve communication on the job site.

There are nearly a million (around 923,100) carpenters in the United States, and the field is set grow by 4% by 2033, adding about 76,500 job openings each year for much of the next decade.

Thinking of joining the industry? It could be a great move!

Whether you’re a total newbie or preparing to launch your own carpentry business, the basics to becoming a carpenter include understanding the industry’s jargon. So, we’re here to help you understand the essential carpentry terms.

This glossary of industry lingo is a key tool because clear communication with clients and teammates is crucial for your success.

In this article, you’ll learn:

- The most important carpentry terms and their meanings.

- How understanding these terms can enhance your carpentry career.

- Practical examples of using these terms in various carpentry tasks.

Let’s get started!

Core Carpentry Terminology

Understanding the foundational and advanced carpentry terms is essential for anyone entering the field. These basic and advanced terms form the backbone of carpentry knowledge, helping you communicate effectively and navigate through both simple and complex projects with confidence.

Basic Carpentry Terms

Here are some foundational terms every carpenter, whether novice or experienced, should be familiar with:

1. Beam

A beam is a horizontal structural element that supports the weight of the building. It’s typically made of wood, steel, or concrete and plays a crucial role in distributing loads from the roof or upper floors down to the foundation.

Beams are used to construct floors, ceilings, and roofs. In a house frame, for example, beams hold up the floor and roof structures, ensuring they remain level and sturdy.

2. Joist

A joist is a horizontal support that runs parallel to the beams and supports the load of the floor or ceiling. It’s commonly made of wood, steel, or engineered materials and is spaced evenly to provide a stable framework.

Joists support floorboards in a flooring system, maintaining the floor’s structural integrity and preventing sagging.

3. Stud

A stud is a vertical framing member within a wall that helps support the structure. Studs are usually made of wood or metal and form a framework to which drywall or other wall materials are attached.

Studs provide a secure frame for attaching drywall, insulation, and other materials. They are installed at regular intervals to ensure the wall can support doors, windows, and fixtures.

4. Plumb

Plumb refers to an object’s vertical alignment. If something is plumb, it means it is perfectly vertical or perpendicular to the ground, ensuring the structure is balanced and straight.

Carpenters frequently check if walls, posts, and beams are plumb during construction to ensure proper installation, such as when hanging a door frame.

5. Level

Level refers to an object’s horizontal alignment. If something is level, it is perfectly parallel to the ground, ensuring even surfaces like floors, countertops, and shelves.

Carpenters use levels to ensure surfaces are perfectly horizontal. For instance, when installing kitchen cabinets, checking for level ensures the cabinets sit evenly, preventing items from rolling off.

6. Miter

A miter is an angled cut made across the face of a material, typically used to create corners in trim or molding where two pieces need to join at an angle.

Carpenters use miter cuts when installing crown molding or baseboards to ensure the pieces fit together seamlessly at corners, resulting in a clean finish.

7. Rafter

Rafters are the sloped framing members of a roof. They run from the ridge (the peak of the roof) down to the eaves, supporting the roof deck and covering materials.

When constructing a building’s roof, carpenters install rafters to create the roof’s slope and support materials like shingles or tiles.

8. Header

A header is a beam placed above an opening, such as a door or window, to support the weight of the structure above it and distribute the load to the surrounding studs.

Headers ensure that door and window openings remain structurally sound, preventing sagging and ensuring smooth operation.

9. Fascia

The fascia is a horizontal board that runs along the edge of the roof, covering the ends of the rafters. It serves both a protective and aesthetic function, often supporting gutters.

Properly installed fascia protects the roof’s edge from weather damage and provides a place to secure gutters, adding to the building’s overall appearance and durability.

10. Lap Joint

A lap joint is created by overlapping two pieces of wood and securing them together, typically with glue, nails, or screws. It’s often used where strength is required.

In frame construction, lap joints connect the corners of wooden frames, providing a strong and durable connection for walls, windows, and doors.

Advanced Carpentry Terms and Phrases

If you’re looking to take your carpentry skills to the next level, understanding these advanced terms is crucial. These terms often come into play in more complex projects that require precision and a deeper knowledge of woodworking techniques:

1. Mortise and Tenon

Mortise and tenon is a classic and durable woodworking joint. The tenon is a protruding part of one piece that fits into a corresponding mortise (hole) in another piece. This joint is known for its strength and ability to hold heavy loads.

In traditional furniture making, mortise and tenon joints are commonly used to join table legs to the tabletop framework. The tenon on the end of the leg fits into the mortise on the table apron, creating a solid connection that can withstand weight and movement over time.

2. Dado

A dado is a groove cut into a piece of wood, usually across the grain. It’s typically used to join two pieces of wood together by inserting one piece into the groove of the other, creating a strong joint.

In cabinetry, dados are used to create shelves that fit snugly into the sides of a cabinet, providing a secure and stable joint that can support heavy loads without the need for additional hardware.

3. Rabbet

A rabbet is an L-shaped cut or notch along the edge or end of a piece of wood. It’s used to allow another piece of wood to fit flush against it, often in cabinetry or when constructing window and door frames.

In picture framing, a rabbet cut along the inside edge of the frame pieces holds the glass, matting, and artwork securely.

4. Dovetail

A dovetail joint consists of interlocking pins and tails, typically used in drawer construction. The shape of the pins and tails provides maximum holding power, making it one of the strongest woodworking joints.

Dovetail joints are often used when constructing drawers to ensure that they can handle frequent opening and closing without weakening.

5. Scribing

Scribing is the process of marking and cutting a material to fit the contours of an irregular surface. It ensures a tight fit between two pieces, especially when working with uneven walls, floors, or other surfaces.

When installing a countertop against an uneven wall, carpenters use a scribing tool to mark the exact contour of the wall onto the countertop, ensuring a seamless fit.

6. Chamfer

A chamfer is an angled cut made along the edge or corner of a piece of wood, usually at a 45-degree angle. It removes the sharp edge for both aesthetic and safety purposes.

Chamfers are often added to table edges to soften the corners, improving the look and preventing injuries from sharp edges.

7. Kerf

The kerf is the width of the cut made by a saw blade. It’s crucial to account for the kerf when making precise cuts to ensure that the pieces fit together as intended.

When cutting wood for framing, carpenters must account for the kerf of the saw blade to avoid ending up with pieces that are too short.

8. Scarf Joint

A scarf joint is a method of joining two pieces of wood end-to-end to create a longer piece. The ends of the wood are cut at complementary angles and then joined together, often using glue or fasteners.

In trim work like baseboards or crown molding, carpenters use scarf joints to splice two pieces together seamlessly when a single piece isn’t long enough.

9. Coping

Coping is a technique used to join two pieces of molding at a corner, ensuring a tight fit. One piece is cut to fit the profile of the other, allowing them to join seamlessly.

When installing crown molding, carpenters cope one piece to match the profile of the adjacent molding, creating a perfect corner joint.

10. Miter Box

A miter box is a tool that helps carpenters make precise miter cuts by guiding the saw at specific angles, usually 45 or 90 degrees.

When installing crown molding or baseboards, a miter box ensures accurate angled cuts, allowing the pieces to fit together cleanly at corners.

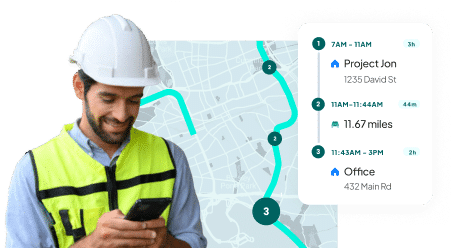

Schedule and pay your team, eliminate time fraud, track project progress, and do much more with Workyard

See how it works

Terminology for Tools and Techniques

Mastery of the tools and techniques used in carpentry is key to producing quality work. From power tools to hand tools, understanding how to measure, cut, and assemble wood accurately allows carpenters to complete tasks efficiently and with precision.

Terminology for Carpentry Tools and Equipment

Knowledge of essential tools and equipment greatly enhances a carpenter’s skill. It is also extra helpful when creating a construction budget. Choosing the right tools and equipment is crucial not only for quality work but also for maintaining a balanced construction budget.

Here are some key tools and their functions that every carpenter should be familiar with:

1. Miter Saw

A miter saw is a power tool used to make precise crosscuts and angled cuts in wood. It’s commonly used for cutting trim, molding, and framing materials. The blade can be adjusted to make angled cuts, allowing carpenters to create miter joints quickly and accurately.

Always keep your hands away from the blade and secure the workpiece with a clamp. Wear safety goggles to protect against wood chips and debris.

2. Router

A router is a versatile power tool used to hollow out or shape the surface of wood. It is often used for decorative edging, cutting grooves, and creating intricate designs. Routers can also be used to create joints like dadoes and rabbets.

If the router is used on a router table, ensure it is securely mounted. Always feed the wood against the direction of the bit’s rotation, and wear hearing protection, as routers can be quite loud.

3. Jigsaw

A jigsaw is a handheld power saw that uses a reciprocating blade to cut curves and shapes in wood, metal, and other materials. It is particularly useful for cutting out intricate designs or working on irregular shapes that a circular saw can’t handle.

Use the correct blade type for the material being cut, and keep fingers away from the blade. Secure the material to prevent it from shifting during cutting.

4. Plane

A plane is a hand tool used to smooth or flatten the surface of wood by shaving thin layers off. It’s ideal for leveling high spots on a board or creating beveled edges. Various types of planes, such as the bench plane, block plane, and jointer plane, are designed for specific tasks.

Always keep the blade sharp and well-adjusted. Use both hands to control the plane and work away from your body to avoid injury.

5. Chisel

A chisel is a hand tool with a sharp cutting edge at the end, used for carving, cutting, or shaping wood. Carpenters use chisels for tasks like cleaning out joints, creating mortises, and removing excess material in detailed woodworking projects.

Always use a chisel with a handle designed for striking and a mallet, not a metal hammer, to avoid damaging the chisel or causing injury. Keep the blade sharp for safer and more effective use.

6. Circular Saw

A circular saw is a power tool with a rotating blade that makes straight cuts in various materials, primarily wood. It’s commonly used to cut lumber, plywood, and other sheet goods quickly and accurately.

Always keep the blade guard in place and avoid cutting freehand. Wear safety goggles to protect against flying debris, and ensure the material is securely supported while cutting.

7. Clamps

Clamps are devices used to hold workpieces securely in place during cutting, gluing, or assembly. They come in various types, including bar clamps, C-clamps, and spring clamps, each designed for different applications.

Make sure clamps are properly tightened to prevent the workpiece from shifting. Avoid overtightening, which can damage the material or tool.

8. Square

A square is a measuring tool used to check and mark right angles (90 degrees) in woodworking. Common types include the carpenter’s square, try square, and combination square. It’s essential for ensuring that cuts and joints are straight and aligned.

While generally safe, be cautious of the edges to avoid cuts. Use the square accurately to prevent measurement errors that could lead to unsafe structural components.

9. Nail Gun

A nail gun is a power tool used to drive nails into wood or other materials quickly and efficiently. It’s commonly used in framing, roofing, and finishing work, greatly speeding up the construction process compared to using a hammer.

Always keep the nail gun pointed away from the body and never bypass the safety mechanism. Wear safety goggles to protect against flying nails and debris.

10. Workbench

A workbench is a sturdy table used as a workspace for various woodworking tasks. It often includes features like built-in clamps and vises to secure materials during cutting, drilling, or assembly.

Ensure the workbench is stable and securely positioned. Keep the surface clear of clutter to avoid accidents, and always secure workpieces properly.

Terms for Measuring and Marking

Precision is key in carpentry, and accurate measurements and markings are essential for ensuring the success of any project. Here are some common terms related to measurement and marking in carpentry:

1. Tape Measure

A tape measure is a flexible, retractable ruler used to measure length, width, and depth. It typically measures 12 to 35 feet and is marked with both imperial and metric units.

Carpenters use tape measures to measure everything from lumber lengths to room dimensions. Their flexibility allows them to measure curved or uneven surfaces.

Ensure the tape is pulled tight and straight for precise measurements. Use the locking mechanism to keep the tape in place while marking.

2. Caliper

A caliper is a precision instrument used to measure the distance between two opposite sides of an object. It is available in digital, dial, and vernier versions and offers high accuracy for small measurements.

Carpenters use calipers to measure the thickness of materials, the diameter of holes, or the width of joints. They’re especially useful in fine woodworking, where precision is crucial.

Ensure the caliper is zeroed before each use. Apply light pressure when measuring to avoid compressing the material and distorting the reading.

3. T-square

A T-square is a T-shaped ruler used primarily for drawing straight lines and right angles. It is commonly used in conjunction with a drawing board.

Carpenters use T-squares to mark straight, accurate lines on wood, particularly when preparing layouts for cuts or assembling joints.

Align the T-square’s head firmly against the edge of the workpiece to ensure your lines are perfectly straight and square.

4. Gauge

A gauge is a tool used for measuring or marking lines at a consistent distance from a reference edge. Common types include marking gauges and depth gauges.

Carpenters use marking gauges to scribe lines parallel to an edge, particularly useful when marking out joints like mortise and tenon.

Set the gauge to the desired measurement before use. Hold the gauge firmly against the wood while scribing to ensure a consistent mark.

5. Spirit Level

A spirit level, also known simply as a level, is a tool with a bubble inside a liquid-filled vial that indicates whether a surface is horizontal (level) or vertical (plumb).

Carpenters use spirit levels to ensure surfaces like floors, shelves, and frames are perfectly horizontal or vertical.

Place the level on a flat surface and read the position of the bubble. For the most precise results, check the level in both directions (horizontal and vertical).

6. Scribe

Scribing is the process of marking a line on a workpiece to match an irregular surface or to serve as a guide for cutting. A scribe is a tool used to scratch a line into the wood.

Carpenters use scribes to transfer the profile of an uneven wall onto a piece of wood, ensuring a tight fit. It’s commonly used in custom fitting countertops, moldings, or flooring.

Hold the scribe at a consistent angle and pressure to ensure a clear, accurate line. Follow the contour of the surface carefully to achieve a precise fit.

7. Awl

An awl is a pointed marking tool used to make small indentations in wood. It helps guide screws or nails to prevent slipping when driving them into place.

Carpenters use an awl to mark drilling points or to create starter holes for screws, ensuring accuracy in positioning hardware.

Apply enough pressure to make a visible mark but avoid excessive force that could split the wood.

8. Chalk Line

A chalk line is a tool that contains a string coated with chalk powder. The string is stretched across a surface and snapped to leave a straight chalk mark.

Carpenters use chalk to mark long, straight lines on surfaces like walls, floors, or lumber. This method is especially useful for aligning tiles, studs, or drywall.

Ensure the string is pulled taut before snapping to get a crisp, straight line. Use a contrasting chalk color to make the line easily visible on different materials.

9. Marking Knife

A marking knife is a tool with a sharp blade used to score precise lines on wood surfaces, often more accurate than a pencil for fine woodworking.

Carpenters use marking knives to outline joints like dovetails and mortises, providing a crisp line that guides the chisel and saw during cutting.

Use a straight edge or ruler as a guide when scoring with the marking knife. Keep the blade sharp for clean, precise lines.

10. Carpenter’s Pencil

A carpenter’s pencil is a flat, rectangular pencil that creates broad, easily visible lines on wood surfaces.

Used for general marking on wood, carpenter’s pencils are ideal for rough layout work, such as marking cut lines or labeling pieces.

Sharpen the pencil to a chisel tip for a fine, controlled line. Use the edge of a square or ruler to guide your marks for straight lines.

Construction and Joinery Terms for Carpenters

Understanding the terms related to construction and joinery helps when working on various construction project types that require specific techniques. So let’s now cover key concepts in construction and the various joinery techniques used to connect pieces of wood effectively.

1. Framing

Framing is the process of building a structure’s skeleton using wooden or metal studs, beams, and other support elements. It forms the basic shape and structure of buildings, including walls, floors, and roofs.

Framing is the foundation of carpentry construction. Carpenters create a framework that defines the building’s layout and supports the walls, roof, and floors.

Proper framing ensures that the structure is stable and can support additional loads like drywall, insulation, and roofing materials.

2. Sheathing

Sheathing refers to the layer of boards or panels attached to a structure’s outer studs, joists, and rafters. It provides a base for exterior coverings, like siding, and adds structural strength to walls, floors, and roofs.

Carpenters use materials like plywood or oriented strand board (OSB) for sheathing to enhance a structure’s rigidity and create a surface for applying finishes like siding or roofing.

Sheathing is crucial for reinforcing the frame, providing a flat surface for exterior materials, and contributing to the building’s overall insulation and weather resistance.

3. Drywall

Drywall, also known as plasterboard or gypsum board, is a panel used to create interior walls and ceilings. It consists of a gypsum core sandwiched between two layers of paper.

Carpenters install drywall sheets to cover the framing of walls and ceilings, providing a smooth surface for painting, wallpapering, or other finishes.

Drywall is essential for constructing interior spaces. It offers a quick and easy way to finish walls and ceilings while providing fire resistance and soundproofing.

4. Subfloor

The subfloor is the layer of material installed directly over the floor joists. It serves as a base for the finished flooring materials, such as hardwood, tile, or carpet.

Carpenters install subflooring using materials like plywood or OSB to create a level surface for the final flooring.

A properly installed subfloor ensures that the finish floor is stable, level, and durable, preventing issues like squeaking or sagging over time.

5. Stud Wall

A stud wall is a non-load-bearing wall made from vertical studs that form a frame to support drywall or other wall coverings. It divides interior spaces without carrying the weight of the structure.

Carpenters build stud walls to create rooms or partitions within a building, allowing for flexible interior design and layout.

Stud walls help organize spaces within a structure and allow for the installation of doors, windows, and electrical components.

6. Butt Joint

A butt joint is the simplest type of joint where two pieces of wood are joined by simply butting them together end-to-end or edge-to-edge. It is usually secured with nails, screws, or glue.

Carpenters use butt joints for basic construction tasks, such as building frames or simple boxes where strength is not the primary concern.

While not the strongest joint, the butt joint is quick and easy to create, making it useful for temporary structures or when reinforced with additional fasteners.

7. Pocket Hole

A pocket hole joint is created by drilling a hole at an angle into one piece of wood and then joining it to another piece with a screw. This method hides the screw and creates a strong connection.

Carpenters use pocket hole joinery for assembling furniture, cabinets, and frames, especially where the joint will not be visible.

Pocket holes provide a strong, hidden joint that is easy to create and can be used on a variety of materials and thicknesses.

8. Biscuit Joint

A biscuit joint is made by inserting a thin, oval-shaped piece of compressed wood (the biscuit) into matching slots cut into the edges of two pieces of wood. Glue is applied, and the biscuit swells, creating a tight joint.

Carpenters use biscuit joints to align and join pieces of wood in panel construction, such as tabletops and cabinet doors.

Biscuit joints are strong and help align pieces accurately, making them ideal for larger surfaces that require precise joining.

9. Half-Lap Joint

A half-lap joint is formed by removing half the thickness of two pieces of wood at the ends so that they overlap and form a flush surface. The joint is then glued and sometimes reinforced with screws or nails.

Carpenters use half-lap joints in framing, furniture construction, and woodworking projects where a flush, strong joint is needed.

Half-lap joints provide more surface area for gluing, resulting in a strong connection while maintaining a flush surface.

10. Bridle Joint

A bridle joint is similar to a mortise and tenon joint, but instead of a hole (mortise), it involves cutting a slot at the end of one piece and a corresponding tenon on the other. The pieces fit together like a puzzle.

Carpenters use bridle joints for frames and structural elements where a strong, visible joint is acceptable.

Bridle joints offer high strength and are easier to make than mortise and tenon joints, making them useful for structural frames.

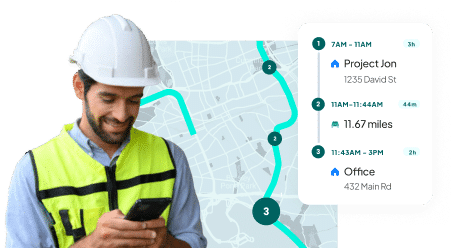

Schedule and pay your team, eliminate time fraud, track project progress, and do much more with Workyard

See how it works

Carpentry Finishing Terms

Finishing is the final step in carpentry, giving projects a polished, professional appearance. Proper finishing enhances the aesthetics of the work and protects the wood and extends the life of the piece. Here are some key finishing terms every carpenter should know:

1. Sanding

Sanding is the process of smoothing the surface of wood using abrasive materials like sandpaper to remove rough spots and surface imperfections.

Carpenters sand wood surfaces before applying any finish to ensure smoothness and proper adhesion of stains or varnishes.

Proper sanding highlights the wood grain and ensures a refined finish. Skipping or rushing sanding can lead to an uneven finish. Always sand progressively with finer grits.

2. Staining

Staining involves applying a colored solution to wood to enhance its natural grain and alter its color. It is used to give wood a desired hue while preserving its natural look, especially on furniture and cabinetry.

Staining adds depth and color to wood, enhancing its visual appeal. Over-applying stains can obscure the wood grain. Apply thin layers and wipe off excess promptly.

3. Varnishing

Varnishing is the application of a clear protective coat over wood surfaces to protect against moisture and scratches.

Applied to furniture, cabinetry, and exterior woodwork to enhance and protect the wood’s natural beauty.

Varnishing adds durability and luster to the wood, providing a high-quality finish. Applying varnish too thickly can cause drips. Use thin, even coats for a smooth finish.

4. Caulking

Caulking involves applying a flexible material to seal gaps and joints in woodwork, preventing air and water infiltration. It is used in trim, baseboards, windows, and doors for a seamless and protective finish.

Proper caulking prevents moisture damage and gives a polished look to the woodwork. Overusing caulk can lead to a messy appearance. Apply sparingly and smooth it for a clean finish.

5. Sealing

Sealing is the application of a sealant to create a barrier on wood surfaces, protecting against moisture and stains. It is used before painting, staining, or varnishing to ensure an even finish, especially on porous woods.

Sealing prevents uneven absorption of finishes, reducing the risk of warping and swelling. Skipping the sealing step can result in blotchy finishes. Always seal porous wood before applying the final finish.

6. Lacquering

Lacquering involves applying a quick-drying protective finish that provides a hard, glossy surface. It is commonly used on furniture and cabinets to create a durable, shiny finish.

Lacquer adds a protective layer that resists water, heat, and scratches. Applying too much lacquer at once can result in a cloudy finish. Apply thin layers and let each coat dry completely.

7. Polyurethane

Polyurethane is a liquid plastic finish that forms a protective layer on wood, available in oil-based and water-based forms. It is applied to floors, furniture, and cabinetry for protection against scratches and moisture.

Offers a durable finish that enhances the wood’s natural beauty. Failing to sand between coats can lead to a rough surface. Lightly sand between each coat for a smooth finish.

8. Wood Filler

Wood filler is a paste used to fill holes, cracks, and imperfections in wood surfaces. It is used to repair nail holes, dents, and gaps before finishing.

Creates a smooth, flawless surface, essential for a professional finish. Overfilling can result in bumps. Apply sparingly and sand the excess once it dries.

9. Bleaching

Bleaching is the process of lightening the wood’s color using chemical agents to remove stains or even out the wood tone. It is used to alter the natural color of the wood or remove unwanted stains before applying a finish.

Bleaching allows for more control over the wood’s final appearance and can create a uniform base for staining. However, over-bleaching can weaken the wood fibers. Use bleach sparingly and follow the product instructions.

10. Burnishing

Burnishing involves polishing wood surfaces using friction to create a smooth, glossy finish without the use of varnishes or lacquers. It is used on fine furniture and turned wood pieces to enhance the natural sheen of the wood.

Burnishing offers a natural, glossy finish that highlights the wood’s texture and grain. Excessive burnishing can generate too much heat, damaging the wood. Apply moderate pressure and work gradually.

Slang and Industry Jargon

Like many trades, carpentry has its own unique slang and industry jargon. These informal terms are commonly used on job sites and in workshops, helping carpenters communicate quickly and effectively.

Understanding this lingo is crucial for anyone in the field, as it can impact safety and efficiency on the job. Besides, it is useful in attracting millennials to construction.

1. Crown

Crown refers to the upward curve or arch in a board, particularly in framing lumber.

A carpenter might say, “Crown up,” indicating that the curved side of the board should face upwards when installed. This positioning ensures that the board will bear weight correctly without sagging.

Knowing how to identify and properly orient the crown helps maintain structural integrity in framing and other construction work.

2. Kickback

Kickback describes the sudden and forceful movement of a workpiece or tool when a saw blade binds or catches on the material.

Carpenters warn, “Watch out for kickback, especially when using power tools like table saws or circular saws.” This is a cautionary reminder to use proper technique and safety measures to avoid injury.

Understanding kickback is vital for safety, as it can cause serious accidents if the carpenter is not prepared or properly positioned.

3. Snipe

A snipe is an unwanted indentation or gouge at the end of a board, typically caused by a planer or jointer.

Carpenters might say, Watch out for snipe, when feeding a board through a planer. It serves as a reminder to support the board properly to minimize snipe.

Knowing how to avoid or correct snipes helps maintain a high-quality finish on wooden pieces, reducing waste and rework.

4. Deadwood

Deadwood refers to framing lumber that is added specifically for nailing purposes, not for structural support.

Carpenters might instruct, Add some deadwood, meaning to install extra pieces of lumber to provide a secure surface for attaching drywall or trim.

Recognizing the use of deadwood helps ensure that all project elements are properly supported and securely fastened.

5. Pitch Pocket

A pitch pocket is a small, resin-filled cavity in wood, typically found in softwoods like pine.

Carpenters might say, That’s got a pitch pocket, indicating the presence of resinous spots that could affect staining or finishing.

Identifying pitch pockets is important for selecting wood for specific applications, particularly when a smooth finish is required.

6. Green Lumber

Green lumber refers to wood that has been recently cut and still contains a high moisture content.

A carpenter might say, That’s green lumber; it needs to dry out, highlighting that the wood should not be used for certain projects until it has dried to prevent warping or shrinkage.

Understanding the term green lumber is crucial for choosing the right materials for a project and ensuring the structural stability of the work over time.

7. Toe Nail

Toe nailing is a method of driving a nail at an angle through the end or edge of one piece of wood into another to secure them together.

Carpenters often use the phrase, Toenail it in, when instructing someone to fasten lumber pieces at an angle, such as when framing a stud wall.

Knowing this technique and its terminology is important for quick and effective fastening in tight or awkward spaces.

8. Rabbit Ear

Rabbit ears refer to the misalignment of two pieces of trim or molding where they meet at a miter joint, causing a visible gap or uneven surface.

A carpenter might point out, Fix the rabbit ears, indicating that the joint needs adjustment to align the trim pieces correctly.

Recognizing and correcting rabbit ears ensures a seamless and professional finish in trim work and molding installations.

9. Skin

Skin refers to the outer layer of a structure, such as drywall, plywood, or siding, that covers the framing.

Carpenters might say, Let’s skin this wall, meaning to cover the wall’s frame with drywall or another surface material.

Understanding this term helps in coordinating tasks on a job site, especially when multiple carpenters are working on different aspects of the project.

If you’re planning to set up a carpentry business, here are some articles that could help:

- How to Start a Carpentry Business

- Carpenter Marketing: How to Get More Leads for Your Business in 2025

- Carpenter Licenses and Certifications: What You Need to Start a Business in the U.S.

- 70 Facts About Carpentry You Need to Know in 2025 (w/ Infographic)

- Carpenter Training: The 5 Best Courses and Schools for Carpentry Careers

- OSHA Violations: A Detailed List (Most Common, Most Serious, and More)

- Everything You Need to Know About Safety Signs in the Workplace

- Carpenter Job Description: Skills, Background, and More (w/ Job Post Template!)

- Carpentry Apprenticeship: How to Become (or Hire) a New Carpenter

- How to Terminate an Employee: A Step-By-Step Guide for Business Compliance and Legal Safety

Why Learn Carpentry Terminology?

Carpenters often work in various arrangements, each with unique implications, like the differences between 1099 and W2 roles in construction businesses. Mastering the terminology used in carpentry:

- enhances your skills,

- improves your communication, and

- elevates your professional credibility.

Let’s look into how understanding these terms can have a profound impact on your career as a carpenter.

1. Professional Growth

Knowing carpentry terms, from beams and joists to advanced joinery, helps you tackle complex projects with confidence. Using the right words shows your skills to colleagues, supervisors, and clients. This boosts your reputation, making you the go-to person for bigger, better-paying jobs.

As you build credibility, more doors open—you can take on leadership roles, get advanced training, or even start your own carpentry business.

2. Client Communication

Clients know what they want but often don’t get the technical side of things. By using clear terms, you can explain what you’re doing and why. For example, you can show why sanding comes before staining for a smooth finish or why crown direction matters in framing.

When you use the right terms, clients trust you more. It sets clear expectations and avoids misunderstandings. Informed clients are happier with the final result, leading to repeat business and referrals.

Using the right words also helps set realistic timelines and costs. For example, explaining the varnishing process and drying times helps clients understand why some steps take time.

3. Efficiency and Accuracy

Knowing carpentry terms helps you work faster and more accurately. You can quickly understand instructions, blueprints, and plans. Whether it’s marking kerfs for blade thickness or knowing the difference between a dovetail and a butt joint, you get it right the first time without needing to ask questions.

Understanding terms like kickback and snipe keeps you safe and reduces costly mistakes. It lets you spot problems early, adjust tools, and avoid ruining materials or delaying the project.

Carpentry demands precision. Knowing measurement and marking terms like caliper, scribe, and gauge ensures accurate cuts and measurements. This means better joints, smoother finishes, and a higher-quality final product.

When everyone on-site speaks the same language, things go smoother. Using common slang like “toenail” or “skin the wall” speeds up work, as everyone understands right away without long explanations.

Understanding state-specific labor laws will also help your business to stay compliant:

- Nevada Labor Laws: A Complete Guide to Wages, Breaks, Overtime, and More (2025)

- Delaware Labor Laws: A Complete Guide to Wages, Breaks, Overtime, and More (2025)

- Kentucky Labor Laws: A Complete Guide to Wages, Breaks, Overtime, and More (2025)

- Michigan Labor Laws: A Complete Guide to Wages, Breaks, Overtime, and More (2025)

- Oklahoma Labor Laws: A Complete Guide to Wages, Breaks, Overtime, and More (2025)

- Vermont Labor Laws: A Complete Guide to Wages, Breaks, Overtime, and More for 2025

- Florida Labor Laws: A Complete Guide to Wages, Breaks, Overtime, and More for 2025

- Wisconsin Labor Laws: A Complete Guide to Wages, Breaks, Overtime, and More (2025)

The Bottom Line

This glossary has covered essential carpentry terms, from basic concepts to advanced joinery techniques and industry slang. Understanding these terms boosts your skills, improves communication, and ensures efficient, precise work on every project.

Using the right terminology is crucial for your growth as a carpenter, whether you’re

- explaining a project to a client,

- working with your team, or

- outlining the scope of work for your next job.

Ready to enhance your carpentry projects? Try Workyard for free to streamline your work and boost productivity.

Words related to carpentry include beam, joist, stud, plumb, level, miter, rafter, header, fascia, and lap joint. These terms are essential for understanding the structural elements and techniques involved in building with wood.

Carpentry also includes tools like saws, hammers, nail guns, and chisels, along with various methods of wood joining, such as mortise and tenon or dovetail joints. These words form the foundation of effective communication and skill in the trade.

Common words associated with carpentry include frame, sheathing, drywall, subfloor, trim, molding, nails, screws, saw, and hammer. These terms relate to the materials and tools used in carpentry work.

Additionally, words like measure, cut, install, joint, and finish describe the processes involved in carpentry. Understanding these words helps in managing carpentry tasks effectively, from initial framing to the finishing touches.

The six key carpentry processes are measuring, cutting, joining, assembling, installing, and finishing. These steps are essential in constructing or repairing wooden structures.

Measuring ensures accuracy, cutting shapes the materials, and joining involves connecting pieces using nails, screws, or glue.

Assembling forms the final structure, while installing involves placing it in its designated space.

Finally, finishing includes sanding, staining, and varnishing to protect and enhance the wood’s appearance.

The 5S in carpentry are Sort, Set in Order, Shine, Standardize, and Sustain.

These principles, adapted from lean manufacturing, help maintain an organized and efficient work environment.

- Sort means removing unnecessary items,

- Set in Order involves arranging tools for easy access,

- Shine focuses on cleaning the workspace,

- Standardize ensures consistent procedures, and

- Sustain refers to maintaining the system over time.

Following the 5S helps carpenters stay productive and reduce waste

Carpenters typically handle framing, installing doors and windows, building cabinets and shelves, laying subflooring, and installing trim and molding.

Framing involves constructing the structure’s skeleton, while door and window installation ensures proper openings.

Cabinets and shelves add storage, subflooring provides a foundation for finished floors, and trim and molding give the project a polished look.

These tasks require precision, planning, and the use of various tools and techniques.

Carpentry operations include measuring, cutting, shaping, joining, finishing, and installing.

Measuring ensures accurate dimensions, while cutting and shaping materials to the required size and form are crucial.

Joining involves connecting wood pieces using nails, screws, or joints. Finishing involves processes like sanding and varnishing to protect and enhance the wood’s appearance.

Finally, installing completed structures or components into their final positions completes the process.