Home Construction Management Construction Procurement

Construction Procurement: A Complete Guide

From best practices to software, here is everything you need to know about construction procurement in one handy guide.

Construction procurement is more than just buying materials – it’s a strategic process that can make or break your projects. Get ahead of the game with our comprehensive guide and unlock procurement success.

In this article, we’ll delve into the world of construction procurement, providing you with a complete understanding of the process, stakeholders involved, best practices, and innovative solutions.

Whether you’re a project manager, contractor, owner, or any other stakeholder involved in construction procurement, this guide is designed to equip you with the knowledge and insights you need to navigate the procurement landscape successfully.

Construction procurement plays a pivotal role in the successful execution of construction projects. It involves obtaining the necessary materials, tools, and services required for a project’s smooth operation, ensuring timely delivery, cost-effectiveness, and adherence to quality standards.

However, navigating the procurement process can be complex, with various factors and challenges to consider.

In this guide, we’ll define construction procurement and explore its significance in construction management. We’ll also dive into the key stakeholders involved in the procurement process and their roles and responsibilities. In addition, you’ll gain valuable insights into the steps involved in construction procurement, from identifying project needs to order management.

We’ll also discuss the factors that influence construction procurement decisions, and we’ll explore different procurement methods commonly used in the construction industry.

So, are you ready to embark on this informative journey into the world of construction procurement?

Let’s dive in and equip ourselves with the knowledge and tools to excel in construction procurement. Together, we’ll navigate the procurement landscape and achieve successful project outcomes.

What Is Procurement in Construction Management?

Construction procurement is the backbone of any successful construction project. It’s the process of obtaining all the necessary materials, tools, and services needed to bring a construction project to life.

Whether you’re building a towering skyscraper, a residential development, or renovating a historic landmark, procurement plays a vital role in ensuring the smooth flow of resources and services.

So, how do we define construction procurement?

At its core, construction procurement involves the strategic acquisition of resources and services to meet project requirements.

It encompasses the entire spectrum of activities, from sourcing and purchasing materials to hiring subcontractors and securing equipment. By effectively managing procurement, construction stakeholders can optimize costs, minimize risks, and streamline project timelines.

Construction procurement involves several key steps. Here’s a brief overview, which we’ll cover in more detail later.

- Define the project’s scope, objectives, and specific needs.

- Determine the type and quantity of materials, equipment, and services required.

- Issue a Request for Proposal (RFP) to potential suppliers, inviting them to submit detailed proposals that outline their offerings, pricing, and delivery schedules. Evaluate these proposals based on criteria such as quality, reputation, experience, and cost.

- Issue purchase orders to selected suppliers, specifying the items, quantities, delivery dates, and other essential details.

- Upon delivery, carefully inspect materials to ensure they meet the specified quality standards and comply with regulatory requirements. Address any discrepancies or defects with the supplier.

Construction procurement is an iterative process that requires constant monitoring, adjustment, and collaboration among all stakeholders involved. By proactively managing procurement activities, construction professionals can optimize resource allocation, enhance project outcomes, and drive overall project success.

Who Is Involved in Construction Procurement?

Construction procurement is a collaborative effort that involves various stakeholders working together to ensure the successful execution of a construction project. Let’s take a closer look at the key players and their roles within the procurement process, starting off with the one in charge.

Construction Project Manager or Construction Procurement Manager

The procurement process is often led by a construction project manager or a dedicated construction procurement manager, depending on the size and complexity of the project.

They are responsible for overseeing the entire procurement process, from initial planning to final delivery. Their duties include identifying project requirements, selecting vendors, negotiating contracts, managing budgets, and ensuring timely procurement of materials and services.

Owner or Client

The owner or client is the individual or organization that initiates and funds the construction project. They have the vision and ultimate authority over the project.

The owner, or client, defines project objectives, provides project specifications, approves budgets, and makes key decisions regarding procurement strategies. They work closely with the project manager to ensure that the project’s procurement aligns with their vision and requirements.

Design Professionals

Design professionals, such as architects and engineers, play a crucial role in the construction procurement process. They are responsible for creating the project’s design, blueprints, and specifications.

Design professionals work closely with the owner/client to understand their requirements and translate them into actionable plans. They provide technical expertise, review supplier qualifications, and ensure that the materials and services procured align with the project’s design and quality standards.

Contractors and Subcontractors

Contractors are the entities responsible for the construction work, while subcontractors are hired by the main contractor to perform specific tasks or provide specialized services.

Both parties collaborate with the project manager to identify the necessary materials, equipment, and services required for the construction process. They may provide input on supplier selection, pricing, and availability. Contractors oversee the coordination of procurement activities with subcontractors and ensure that materials are delivered to the construction site on time.

Suppliers and Vendors

Suppliers and vendors are the entities that provide the necessary materials, equipment, and services required for the construction project.

Both parties play a critical role in the procurement process by sourcing, manufacturing, or distributing construction materials and equipment. They collaborate with the project manager to understand project specifications, deliver goods and services on time, and maintain quality standards. They may also provide technical support, warranties, and after-sales services.

Regulatory Authorities

Regulatory authorities include government agencies, local authorities, and industry-specific regulatory bodies.

They enforce compliance with building codes, safety regulations, environmental standards, and other legal requirements. They may review and approve procurement-related documents, inspect materials, and ensure that the construction project meets all necessary regulations.

Steps Involved in Construction Procurement

The procurement process in construction management follows a series of steps to ensure the successful acquisition of products and services. In this section, we’ll explore each stage in detail.

Stage 1: Identify a Need for Products and Services

The first step in construction procurement is identifying the specific products and services required for the project. This involves understanding the project scope, design specifications, and materials needed.

Key Milestones

- Defining the project requirements

- Conducting market research to identify potential suppliers

- Creating a comprehensive list of needed items

Tip #1: Clearly communicate project needs and specifications to all stakeholders involved.

Tip #2: Engage with design professionals, contractors, and suppliers early in the process to gather input and ensure alignment.

Stage 2: Create and Submit a Purchase Request

Once the need for products and services is identified, a purchase request is created. This document outlines the details of the required items, quantities, quality standards, and any specific delivery timelines.

Key Milestones

- Generating a comprehensive purchase request

- Ensuring accuracy and completeness

- Obtaining necessary approvals

Tip #1: Provide clear and detailed information in the purchase request to avoid misunderstandings and delays.

Tip #2: Involve all relevant stakeholders, such as project managers and design professionals, to validate the purchase request before submission.

Stage 3: Evaluate and Select Suppliers/Vendors

In this stage, potential suppliers/vendors are evaluated based on criteria such as reputation, quality, pricing, delivery capabilities, and compliance with regulatory requirements.

Key Milestones

- Issuing a request for proposal (RFP) to potential suppliers

- Reviewing and evaluating proposals

- Conducting supplier assessments

- Shortlisting candidates.

Tip #1: Clearly define evaluation criteria and weight them based on project priorities.

Tip #2: Ensure a transparent and fair evaluation process, and consider factors beyond price, such as supplier reliability and compatibility with the project’s goals.

Stage 4: Negotiate the Terms of a Contract with the Selected Supplier

Once a preferred supplier is selected, negotiations begin to establish the terms and conditions of the contract. This includes pricing, delivery schedules, warranties, payment terms, and any other relevant contractual obligations.

Key Milestones

Engaging in negotiations, reaching mutually beneficial agreements, and finalizing the contract terms.

Tip #1: Conduct thorough market research to understand pricing benchmarks and industry standards.

Tip #2: Prepare by setting clear negotiation objectives, understanding the supplier’s perspective, and being open to compromise while safeguarding project interests.

Stage 5: Finalize a Purchase Order

After contract negotiations, a purchase order is generated. This formal document specifies the agreed-upon terms, quantities, delivery dates, and any other relevant details. It serves as a legally binding agreement between the buyer and the supplier.

Key Milestones

Preparing and reviewing the purchase order, obtaining necessary approvals, and sharing it with the supplier.

Tip #1: Double-check the accuracy of all information in the purchase order, ensuring that it aligns with the contract terms.

Tip #2: Maintain effective communication channels with the supplier to address any concerns or clarifications.

Stage 6: Order Management

Once the purchase order is finalized, it’s crucial to effectively manage the procurement process. This involves tracking the status of orders, coordinating deliveries, addressing any issues or delays, and ensuring timely receipt of materials and services.

Key Milestones

Monitoring order progress, managing communication with suppliers, conducting quality inspections, and resolving any discrepancies.

Tip #1: Establish clear lines of communication with suppliers to facilitate information exchange.

Tip #2: Regularly track and update the status of orders, anticipate and address potential delays, and maintain a proactive approach to order management.

Factors Affecting Construction Procurement

Construction procurement decisions are influenced by a variety of factors that impact project success. Let’s explore some common factors that play a crucial role in shaping construction procurement strategies.

1. Project Requirements

Scope and Complexity

The size and complexity of the project dictate the procurement approach. Larger projects with intricate designs and specialized requirements may necessitate longer procurement lead times and more extensive supplier evaluation.

Design Specifications

Unique design elements and materials may require engaging specific suppliers or manufacturers with the expertise and capacity to meet project specifications.

Quality Standards

Projects with stringent quality requirements may involve more rigorous supplier qualification processes and additional quality control measures.

2. Time Constraints

Project Timelines

Construction projects often have strict deadlines. Procurement strategies must align with project schedules to ensure timely delivery of materials and services. Considerations include lead times for manufacturing or sourcing, transportation, and on-site installation or assembly.

Fast-track Projects

Projects with accelerated schedules may require alternative procurement methods, such as design-build or off-site fabrication, to expedite the process.

3. Budget

Cost Considerations

Budget constraints influence procurement decisions, with a focus on obtaining the best value for money. Evaluating suppliers’ pricing structures, negotiating favorable terms, and seeking cost-effective alternatives without compromising quality is essential.

Cost Predictability

Construction projects often face uncertainties in pricing due to volatile material costs and market fluctuations. Strategies to address cost predictability, such as long-term contracts, pricing escalation clauses, or hedging against price fluctuations, can be employed.

4. Supplier Capabilities

Supplier Capacity

The ability of suppliers to meet project demands in terms of capacity, resources, and expertise is critical. Assessing their track record, production capabilities, financial stability, and compliance with relevant regulations helps ensure reliable and capable suppliers.

Supplier Relationships

Establishing strong relationships with suppliers can lead to improved collaboration, better communication, and potential cost savings. Maintaining positive relationships fosters trust and facilitates smoother procurement processes.

5. Sustainability and Environmental Considerations

Environmental Regulations

Compliance with environmental standards and regulations is crucial in modern construction projects. Procurement decisions may prioritize suppliers with sustainable practices, environmentally friendly materials, and a commitment to minimizing the project’s ecological footprint.

Green Certifications

Projects aiming for green certifications, such as LEED (Leadership in Energy and Environmental Design), may require procuring materials and services from suppliers with specific environmentally conscious credentials.

6. Risk Management

Supply Chain Risks

Construction procurement involves inherent risks such as supply chain disruptions, supplier failures, and quality issues. Mitigation strategies, such as diversifying suppliers, conducting risk assessments, and implementing contingency plans, are essential to minimize project delays and financial impacts.

Legal and Contractual Risks

Procurement decisions should consider legal and contractual risks, including compliance with regulatory requirements, intellectual property rights, and dispute resolution mechanisms.

7. Stakeholder Collaboration

Collaboration with Stakeholders

Effective collaboration and coordination among project stakeholders, including owners/clients, designers, contractors, and suppliers, is crucial for successful procurement. Transparent communication, early involvement, and shared decision-making contribute to efficient procurement processes.

Streamline your construction management with Workyard.

Try free

Alternative Construction Procurement Methods

In the construction industry, various alternative procurement methods have emerged to address different project needs and objectives. Let’s explore some commonly used methods.

1. Traditional Design-Bid-Build

In the traditional design-bid-build method, the project owner/client first hires a design team (architects and engineers) to create the project design and specifications.

Once the design is complete, the project is put out to bid, and contractors submit competitive bids. The owner selects the winning bid, and the chosen contractor constructs the project based on the predetermined design.

Advantages

- Clear separation of design and construction responsibilities.

- Competitive bidding may result in lower costs.

- Well-established method with a long history in the industry.

Disadvantages

- Limited collaboration between the design and construction teams.

- Potential for miscommunication or conflicts between parties.

- May result in longer project timelines due to sequential processes.

2. Design-Build

In the design-build approach, a single entity (design-build contractor or a team of professionals) is responsible for both the design and construction aspects of the project.

The owner/client contracts directly with the design-build entity, which takes on the entire project from start to finish.

Advantages

- Single point of responsibility streamlines communication and decision-making.

- Potential for faster project completion due to concurrent design and construction activities.

- Increased collaboration and potential for innovation during the design phase.

Disadvantages

- Limited owner control over the design process.

- Potential for conflicts of interest if the design-build entity is biased towards its own construction interests.

- Design changes during construction can lead to additional costs.

3. Joint Venture

Characteristics

A joint venture occurs when two or more entities, typically contractors or developers, combine their resources, expertise, and capital to undertake a construction project together. Each party contributes to the project based on their respective strengths and capabilities.

Advantages

- Shared risks and responsibilities among joint venture partners.

- Access to a broader pool of resources, expertise, and financial capacity.

- Enhanced competitiveness in securing larger or more complex projects.

Disadvantages

- Potential for conflicts and disagreements among joint venture partners.

- Decision-making may be slower due to the need for consensus.

- Unequal contributions or disparities in expertise can create challenges.

4. Private Financing

Characteristics

Private financing involves securing funding for a construction project from private sources, such as banks, investors, or private equity firms, rather than relying solely on traditional public financing sources. The private financiers provide the necessary capital in exchange for a return on their investment.

Advantages

- Greater flexibility in project funding and potentially faster access to capital.

- Reduced reliance on public funding and associated bureaucratic processes.

- Potential for innovative financing structures and terms.

Disadvantages

- Higher financing costs due to interest rates and investor expectations.

- Increased risk associated with private financing arrangements.

- Limited availability of private financing for certain types of projects.

Pros and Cons of Construction Procurement Methods

Now that we know all the methods of construction procurement, let’s explore all of the options side-by-side.

Pros | Method | Cons |

– Efficient project oversight – Flexibility in decision-making – Strong collaboration between stakeholders – Ability to adapt to project changes | Construction Management | – Potential for higher costs due to additional management complexities – Possible challenges in coordination and communication – Dependence on the expertise and availability of a skilled project manager |

– Clear separation of design and construction responsibilities – Potential for competitive bidding and lower costs – Well-established method with industry familiarity – Owner has greater control over design decisions | Traditional Design-Bid-Build | – Sequential process can lead to longer project timelines – Limited collaboration between design and construction teams – Potential for miscommunication or conflicts between parties |

– Streamlined communication and decision-making – Potential for faster project completion – Increased collaboration and potential for innovation – Single point of responsibility throughout the project | Design-Build | – Limited owner control over the design process – Potential conflicts of interest with the design-build entity – Design changes during construction may lead to additional costs |

– Shared risks and responsibilities among partners – Access to a broader pool of resources and expertise – Enhanced competitiveness in securing larger projects – Ability to tackle larger or more complex projects | Joint Venture | – Potential conflicts and disagreements among partners – Decision-making may be slower due to consensus – Disparities in contributions or expertise can create challenges |

– Greater flexibility and faster access to capital – Reduced reliance on public funding – Potential for innovative financing structures – Can overcome bureaucratic processes associated with public funding | Private Financing | – Higher financing costs due to interest rates and investor expectations – Increased risk associated with private financing arrangements – Limited availability of private financing for certain projects |

Best Practices in Construction Procurement

To ensure successful construction procurement, it is important to follow best practices that apply to all methods. These practices help streamline the procurement process, enhance collaboration among stakeholders, and mitigate risks. Let’s explore some key best practices.

Conduct Thorough Market Research

Stay updated on industry trends, technological advancements, and market dynamics that may impact the availability and pricing of construction materials, equipment, and services.

Research and evaluate potential suppliers based on their track record, reputation, financial stability, and ability to meet project requirements.

Clearly Define Project Scope

Clearly define the project’s objectives, specifications, quality standards, and timeline. This ensures that all stakeholders have a shared understanding of the project’s scope and expectations.

Involve architects and engineers from the outset to align project requirements with design specifications and address potential conflicts or challenges in procurement.

Establish Transparent and Fair Selection Criteria

Clearly establish the criteria and weighting system for evaluating potential suppliers. Consider factors such as price, quality, experience, technical capabilities, compliance with regulations, and sustainability practices.

Conduct evaluations and supplier selections in a fair and transparent manner, following predefined criteria and documenting the decision-making process.

Promote Collaboration and Communication Among Stakeholders

Involve relevant stakeholders, including owners/clients, design professionals, contractors, and suppliers, from the early stages of procurement planning to facilitate collaboration, gather input, and align expectations.

Establish effective communication channels and regular meetings to share project updates, address concerns, resolve issues, and ensure all stakeholders are on the same page.

Implement Robust Contract Management and Oversight Mechanisms

Clearly define the roles, responsibilities, deliverables, and timelines of all parties involved. Include provisions for change management, dispute resolution, quality control, and risk allocation.

Implement systems to monitor supplier performance, ensuring compliance with contractual obligations, quality standards, and delivery schedules. Address any performance issues promptly and collaboratively.

Emphasize Risk Management

Conduct a comprehensive risk assessment to identify potential risks associated with procurement, such as supply chain disruptions, price fluctuations, or regulatory compliance issues. Develop mitigation strategies and contingency plans.

Avoid overreliance on a single supplier by diversifying the supply chain. Have backup options and alternative suppliers to mitigate potential disruptions.

Embrace Technology and Automation

Implement digital procurement tools and software solutions to streamline the procurement process, enhance transparency, automate workflows, and improve efficiency.

Leverage data analytics to gain insights into procurement patterns, supplier performance, and market trends, enabling better decision-making and cost optimization.

Construction Procurement Software

Construction procurement software is a specialized technological solution designed to streamline and optimize the procurement process within the construction industry.

It leverages digital tools and automation to overcome common challenges faced in construction procurement, including budget constraints, time delays, disputes, quality control, and sustainability considerations. Let’s explore how construction procurement software addresses these challenges.

Budget Constraints and Cost Overruns

Procurement software enables accurate tracking of procurement costs, providing visibility into spending and budget utilization. This helps identify potential cost overruns early on and enables proactive cost management.

Construction procurement software facilitates the process of soliciting competitive bids, evaluating suppliers based on pricing and other criteria, and selecting the most cost-effective options.

Software solutions generate detailed reports and analytics, providing insights into procurement costs, trends, and potential cost-saving opportunities.

Time Delays and Schedule Management

Procurement software automates and streamlines the procurement process, reducing manual tasks and paperwork. This saves time and enables faster decision-making and approvals.

The software provides a centralized platform for stakeholders to communicate, share information, and collaborate in real time, improving coordination and reducing delays.

Procurement software sends automated notifications and reminders for critical procurement milestones, ensuring that tasks are completed on time and avoiding schedule disruptions.

Disputes and Conflicts

Construction procurement software facilitates effective contract management, storing all contract-related information and documentation in a centralized repository. This ensures clarity and transparency in contract terms, reducing the likelihood of disputes.

The software creates an audit trail, tracking all procurement activities, decisions, and changes. This provides a historical record that can be referenced in case of disputes, supporting effective resolution.

Procurement software improves collaboration among stakeholders, enabling transparent communication and real-time visibility into procurement processes. This fosters trust, minimizes misunderstandings, and reduces the likelihood of conflicts.

Quality Control and Assurance

Construction procurement software facilitates supplier qualification and performance tracking, ensuring that only qualified and reliable suppliers are engaged. It enables ongoing assessment and monitoring of supplier performance, promoting adherence to quality standards.

The software allows for the documentation and management of quality inspections, ensuring that materials and services meet specified quality requirements. It can also track certifications and compliance with regulatory standards.

Procurement software helps manage non-conformance issues, tracking and resolving quality-related problems promptly and efficiently. It facilitates communication with suppliers to address non-conformities and ensure corrective actions are taken.

Sustainability and Environmental Considerations

Construction procurement software supports the evaluation and selection of suppliers based on their sustainability practices, environmental certifications, and social responsibility commitments.

The software enables the inclusion of sustainability criteria in procurement documentation, such as RFPs and contracts. It ensures that sustainability considerations are monitored and met throughout the procurement process.

Construction procurement software provides tools for tracking and reporting on environmental impact, enabling the measurement of carbon footprints, waste reduction initiatives, and adherence to sustainability goals.

How Workyard Can Help

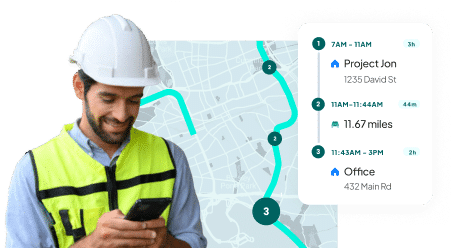

Workyard offers innovative construction management software that can revolutionize your project planning, execution, monitoring, and payment processing.

With its user-friendly interface and robust features, Workyard empowers construction professionals to streamline inefficient processes and enhance project outcomes.

Workyard simplifies project planning and scheduling by providing a centralized platform for all project-related information. You can easily define project requirements, create detailed project plans, and allocate tasks to team members. The software’s intuitive job scheduling tools help you efficiently manage timelines, track progress, and identify potential bottlenecks, ensuring projects stay on track.

With Workyard, you can seamlessly collaborate with stakeholders throughout the project lifecycle. The software enables effective communication, document sharing, and real-time updates, fostering collaboration among owners/clients, design professionals, contractors, and suppliers. This ensures smooth project execution, reduces rework, and enhances overall project delivery.

Workyard provides comprehensive monitoring and reporting capabilities, allowing you to track project progress, budgets, and project milestones. Real-time dashboards and analytics offer valuable insights into project performance, enabling data-driven decision-making. You can easily identify areas of improvement, proactively address issues, and optimize workflows for future projects.

By leveraging the power of Workyard, construction professionals can enhance collaboration, improve project efficiency, mitigate risks, and achieve successful project outcomes. Ready to experience the benefits of Workyard for yourself? Sign up for a free trial of Workyard today.