Home Construction Management HVAC Terms

HVAC Terms: A Glossary of Industry Lingo + Detailed Definitions

Learning about the HVAC business? This glossary of commonly used HVAC terms and phrases will help you sling lingo like an old pro!

Looking to learn more about HVAC terms and definitions?

We know this industry has tons of lingo to get familiar with, and it would probably be easier if you had a single source of HVAC terminologies you could always turn to.

This definitive compilation of HVAC terms should give you a basic understanding of all the key concepts and practices commonly encountered in the U.S. heating, ventilation, and air conditioning (HVAC) industry.

Whether you’re an apprentice still learning the ropes at your new job or an experienced technician who wants to brush up on your HVAC knowledge, this glossary should give you a leg up.

Use this HVAC glossary regularly and it will help you breeze through learning and warm up to the profession in no time (puns definitely intended!).

Let’s start alphabetically…

HVAC Terms A – F

A

Absolute pressure: The total pressure measured relative to a complete vacuum. In HVAC, absolute pressure is important for understanding system pressures, as it includes atmospheric pressure in the calculation.

ACCA (Air Conditioning Contractors of America): A nonprofit association of HVAC professionals that develops industry standards and provides education and resources for HVAC contractors.

Accumulator: A device in refrigeration systems that prevents liquid refrigerant from reaching the compressor, helping to maintain proper system operation and protect components from damage.

AC fans: Fans powered by alternating current, used in HVAC systems to move air for ventilation, cooling, or heating.

AC (Alternating Current): An electric current in which the flow of electric charge periodically reverses direction. In HVAC, AC power is commonly used to run motors, fans, and compressors in systems.

Acoustical: Refers to the sound properties of a space or material. In HVAC, acoustics are important for designing quiet systems and minimizing noise generated by equipment such as air conditioners, fans, or ducts.

ACIS™ (Air Conditioning Intelligent Systems): A brand or system focused on enhancing the control and efficiency of air conditioning units using advanced monitoring and automation technologies.

Adiabatic cooling: A process where temperature changes occur without heat exchange. In HVAC, adiabatic cooling often refers to systems that use evaporative cooling without adding heat to the surroundings.

AFUE (Annual Fuel Utilization Efficiency): A measure of a gas furnace’s efficiency. It shows how much energy is converted into usable heat during a typical year, expressed as a percentage. Higher AFUE ratings indicate more efficient systems.

AGA (American Gas Association): A trade organization representing natural gas companies. In HVAC, AGA provides certifications and standards for gas appliances used in heating systems.

AHRI (Air-Conditioning, Heating, and Refrigeration Institute): An industry trade association that develops performance standards for HVACR equipment, including testing and certification programs.

AHU (Air handling unit): A device used to regulate and circulate air as part of an HVAC system. AHUs typically contain fans, heating or cooling coils, filters, and dampers to condition and distribute air.

Air Conditioner: A system that removes heat from an indoor space to lower the temperature, commonly using a refrigeration cycle. Air conditioners are widely used for cooling in residential and commercial buildings.

Air-cooled system: An HVAC system that uses air, rather than water, to cool refrigerant. Typically, air-cooled systems are less complex and more affordable but may be less efficient than water-cooled systems.

Air diffuser: A component of HVAC systems that evenly distributes air into a room. It directs airflow in specific patterns to optimize comfort and maintain even temperature distribution.

Airflow Volume: The amount of air passing through an HVAC system, typically measured in cubic feet per minute (CFM). Proper airflow volume is critical for the efficiency and performance of heating and cooling systems.

Ambient: Refers to the surrounding environmental conditions, such as temperature and humidity. In HVAC, ambient temperature is important for system design and performance calculations.

Application: In HVAC, “application” refers to the specific use or purpose for which a system or component is designed. For example, HVAC systems may be designed for residential, commercial, or industrial applications.

ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers): A global organization that advances HVACR technology through research, standards development, and professional education.

Azeotrope/azeotropic mixture: A blend of refrigerants that behaves as a single substance, maintaining a constant composition during phase changes. Azeotropic refrigerants are often used in HVAC systems for their stable performance.

Azeotropic point: The specific temperature and pressure at which an azeotropic mixture exhibits phase change without changing its composition, making it useful for efficient refrigeration in HVAC systems.

Azeotropic refrigerants maintain a constant boiling point during phase changes, meaning the liquid and vapor phases have the same composition. This makes them more stable and efficient than non-azeotropic blends, which experience “glide.” The consistent performance of azeotropes improves efficiency and predictability in HVAC systems.

B

BEMS (Building Energy Management System): A computer-based system that controls and monitors a building’s HVAC, lighting, and other mechanical systems. It helps optimize energy use, improve comfort, and reduce operational costs.

Blend: In HVAC, this term refers to a mixture of different refrigerants. Blends are designed to combine properties of multiple refrigerants to optimize performance for specific applications, such as better efficiency or environmental compliance.

Blower Motor: A component whose primary function is to drive the fan that moves air through the ducts in the HVAC system.

BREEAM (Building Research Establishment Environmental Assessment Method): A widely recognized method for assessing, rating, and certifying the sustainability of buildings. HVAC systems play a critical role in a building’s overall BREEAM rating, particularly in energy efficiency and indoor air quality.

BTU (British Thermal Unit ): A unit of energy used in HVAC to measure the heat output of systems. One BTU is the amount of heat required to raise the temperature of one pound of water by one degree Fahrenheit.

BTU/h (British Thermal Units per Hour): A measurement of heat transfer rate. It indicates how many BTUs are transferred each hour, typically used to describe the capacity of HVAC systems.

Bubble point: The temperature at which a liquid refrigerant begins to vaporize at a given pressure. Understanding the bubble point is essential in HVAC systems for proper refrigerant management and efficiency.

Burner: A component in a gas furnace where fuel is mixed with air and ignited to produce heat. Burners are critical for generating heat in heating systems.

Burner Orifice: A small opening in the burner that controls the flow of gas into the combustion chamber. The size of the orifice is crucial for regulating the air-to-fuel ratio, affecting the efficiency and safety of the burner.

C

Capacity: In HVAC, this refers to the ability of a system to heat or cool a space, usually measured in BTUs or tons. The capacity must match the size and needs of the space for optimal performance.

Capillary tube: A thin tube used in HVAC systems as an expansion device, controlling the flow of refrigerant into the evaporator. It helps regulate pressure and ensures efficient heat exchange.

Cascade system: A refrigeration system that uses two or more separate refrigeration circuits to achieve extremely low temperatures. Each stage cools the next, providing more precise and efficient cooling for specialized applications.

Cassette unit: A type of air conditioning system typically mounted in a ceiling, with the grille exposed to the room. It provides effective cooling or heating for large areas without taking up floor or wall space.

Celsius: A temperature scale where water freezes at 0°C and boils at 100°C at sea level. HVAC systems often use Celsius for temperature control in non-U.S. countries.

Centrifugal compressor: A type of compressor that uses centrifugal force to compress the refrigerant and move it through the HVAC system. Commonly used in large commercial HVAC systems, it is known for its ability to handle high flow rates.

CFC (Chlorofluorocarbon): A type of refrigerant once widely used in HVAC systems, but now largely banned due to its ozone-depleting properties.

CFM (Cubic Feet per Minute): A measurement of airflow, indicating how many cubic feet of air pass through a system each minute. It is a critical factor in determining the capacity and efficiency of an HVAC system.

Charging a System: The process of adding refrigerant to an HVAC system to ensure it operates at optimal efficiency. Proper charging is essential for maintaining performance and prolonging the life of the system.

Chilled water system: A cooling system that uses water chilled by a chiller to cool air in a building. It is often used in large commercial or industrial buildings for air conditioning.

Chiller: A device that removes heat from water through refrigeration and provides chilled water for cooling buildings. Chillers are a central component in large commercial HVAC systems.

Clean room: A controlled environment where pollutants like dust, microbes, and aerosol particles are minimized. HVAC systems for clean rooms are highly specialized to maintain strict air quality and filtration standards.

Close control/Climate control: Refers to HVAC systems designed to maintain precise temperature and humidity levels, often used in environments like data centers, laboratories, or clean rooms.

Cold aisle: In data center HVAC, this refers to a configuration where cold air is directed into aisles between rows of server racks to cool equipment more effectively.

Comfort air conditioning: A type of air conditioning designed to maintain comfortable indoor temperatures and humidity levels for human occupants.

Commercial air conditioning: Large-scale air conditioning systems used in commercial buildings such as offices, hotels, and retail spaces. These systems often have higher capacity and different design considerations compared to residential systems.

Commissioning: The process of testing and verifying that an HVAC system is installed correctly and operates as intended. It ensures the system meets design specifications and works efficiently.

Compressor: A key component of HVAC systems that compresses refrigerant gas and moves it through the system. It is responsible for maintaining the pressure necessary for the refrigeration cycle to function.

Condensate: The water that forms when warm, moist air comes into contact with a cold surface, such as an evaporator coil. In HVAC systems, condensate is collected and drained away to prevent water damage.

Condenser: A component in HVAC systems where refrigerant releases heat to the surrounding air or water, allowing it to return to a liquid state before circulating back to the evaporator.

Condenser Coil: The part of the air conditioning system that expels heat absorbed by the refrigerant. The coil releases this heat into the outdoor air, facilitating the cooling process.

Condenser Fan: A fan that blows air over the condenser coil to help release heat absorbed by the refrigerant. It improves the efficiency of the cooling process in HVAC systems.

Condensing unit: The outdoor part of a split-system air conditioner or heat pump, containing the compressor, condenser coil, and fan. It is responsible for releasing heat collected from the indoor air.

Conduction: The transfer of heat through direct contact between materials. In HVAC, conduction plays a role in heat gain or loss through walls, floors, and windows.

Constant air volume (CAV): A type of HVAC system that delivers a constant volume of air to a space, with the temperature of the air being adjusted to meet heating or cooling needs.

Controls: Refers to the devices and systems used to regulate HVAC equipment, such as thermostats, sensors, and automation systems that control temperature, humidity, and airflow.

Convection: The transfer of heat through the movement of air or liquid. In HVAC systems, convection is used to circulate warm or cool air throughout a building.

COP (Coefficient of Performance): A measure of the efficiency of an HVAC system, particularly heat pumps. It compares the amount of heating or cooling provided to the energy consumed, with higher values indicating better efficiency.

Cooling tower: A device that removes heat from water by evaporating a portion of the water, which cools the remaining liquid. Cooling towers are used in large HVAC systems to expel heat from the building.

CRAC (Computer Room Air Conditioner): A specialized air conditioning unit designed to maintain optimal temperature and humidity in data centers and server rooms.

CRAH (Computer Room Air Handler): Similar to CRAC, CRAH units use chilled water to remove heat from server rooms, providing cooling in environments where precise temperature control is critical.

CUE (Carbon Usage Effectiveness): A metric used to measure the carbon emissions produced relative to the amount of IT energy used in data centers. HVAC systems in data centers play a crucial role in lowering CUE by optimizing cooling efficiency.

CWR (Chilled Water Return): The water returning to a chiller after it has absorbed heat from the building. Chilled water return is part of the closed-loop system used in large commercial HVAC systems.

CWS (Chilled Water Supply): The water that is supplied from the chiller to the building’s air handling units or fan coils to absorb heat and cool the space.

D

Damper: A device located in ductwork that regulates the flow of air within an HVAC system. Dampers can be manually or automatically adjusted to control airflow to different zones or rooms.

Data Centre: A facility that houses servers and IT equipment, requiring precise climate control for optimal performance. HVAC systems in data centers are designed to maintain specific temperatures and humidity levels to prevent overheating.

DATS (Discharge Air Temperature Sensor): A sensor used in HVAC systems to measure the temperature of the air as it exits the air handler or furnace. It helps regulate and control heating or cooling by ensuring the air delivered to spaces is at the desired temperature.

DC (Direct Current): A type of electrical current where the flow of electricity is in a single direction. In HVAC, DC-powered fans and motors are often used for their efficiency and ability to adjust speeds.

Decant/receiver: A component in refrigeration systems where liquid refrigerant is stored before it is fed into the evaporator. The receiver ensures that only liquid refrigerant enters the expansion device.

Dehumidification: The process of removing moisture from the air. Dehumidification improves indoor air quality and comfort, especially in humid climates. It’s an essential function of many HVAC systems.

Dehumidifier: A device that removes excess moisture from the air, typically used to control humidity levels in a building. Dehumidifiers are critical in maintaining comfort and preventing mold growth in humid environments.

Degree-Day: A measurement used to estimate the heating or cooling requirements of a building. It is calculated by subtracting the average outdoor temperature from a base temperature (usually 65°F or 18°C). This helps HVAC professionals determine the energy needs for heating or cooling.

Density: In HVAC, density refers to the mass of air per unit volume. It affects airflow and heat transfer in heating and cooling systems.

Detent: A mechanical or electrical component that maintains a part in a specific position or restricts its movement until a force is applied. In HVAC, detents are often used in switches and controls to provide tactile feedback or lock components into position.

Dew Point: The temperature at which air becomes saturated with moisture and water vapor begins to condense into liquid. HVAC systems must account for the dew point to prevent condensation on cooling coils and ducts.

Diffuser: A device placed over an air supply outlet in HVAC systems that distributes conditioned air evenly into a room. Diffusers help control the direction and flow of air to improve comfort.

Direct Expansion Systems (DX): A type of cooling system where the refrigerant is directly evaporated within the air handling unit or fan coil, allowing it to cool air without a secondary chilled water loop. DX systems are commonly used in small to medium-sized commercial spaces.

DOE (Department of Energy): A U.S. government agency responsible for developing policies related to energy use. In HVAC, DOE regulations influence energy efficiency standards for air conditioners, furnaces, and other equipment.

Downflow: Refers to an HVAC system design where air is taken in from the top and discharged downward. Downflow systems are often used in homes with basements or crawl spaces.

Downflow Furnace: A type of furnace in which air is drawn in from the top, heated, and then discharged downward into the ductwork. This configuration is typically used when ductwork is located below the furnace, such as in basements.

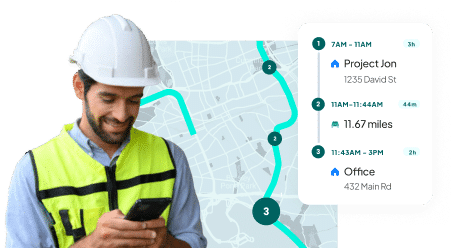

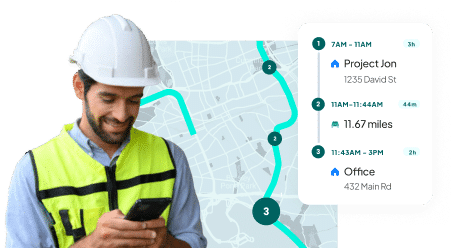

Boost HVAC techs’ productivity with Workyard’s precise time clock

See how it works

Drain Pan: A shallow pan installed beneath cooling coils or condensers to collect and drain away condensate formed by the cooling process. Proper drainage is essential to prevent water damage in HVAC systems.

Drop-in: Refers to refrigerants that can be used as a replacement in existing HVAC systems without significant modifications. Drop-in refrigerants are designed to replace older, environmentally harmful refrigerants like CFCs.

Dry Bulb Temperature: The temperature of air measured with a thermometer, excluding the effects of humidity. It is the most commonly referenced air temperature in HVAC design and is used to calculate heating and cooling loads.

Duct: Tubes or conduits used to distribute conditioned air throughout a building. Ductwork is essential for delivering heated or cooled air from the HVAC system to different rooms.

Duct work: The entire system of ducts in a building that distributes air from the heating, ventilation, and air conditioning systems to various rooms. Properly designed ductwork is essential for efficient airflow and comfort.

Ductless mini-split system: A type of HVAC system that provides heating and cooling without ductwork. It consists of an outdoor compressor/condenser and one or more indoor air-handling units, known as heads. Each head is individually controlled, offering the ability to create zones within a building.

DX (Direct Expansion): Refers to HVAC systems that cool air directly using refrigerant. In a DX system, the refrigerant evaporates in the coil and cools the air passing over it. These systems are widely used in residential and commercial buildings for cooling.

E

EC fan (Electronically Commutated Fan): A type of fan that uses a brushless DC motor, providing better energy efficiency and control compared to traditional AC motors. EC fans are commonly used in HVAC systems due to their ability to reduce energy consumption and provide variable speed control.

Economiser: A system that reduces energy consumption in HVAC by using outdoor air for cooling when conditions are suitable, instead of relying on mechanical cooling. Economisers are often used in commercial buildings to improve energy efficiency.

EER (Energy Efficiency Ratio): A measure of the efficiency of an air conditioning or refrigeration system. It is calculated by dividing the cooling output (in BTUs) by the power input (in watts) at a specific operating point. Higher EER values indicate more efficient systems.

Electronic Expansion Valve (EEV): A valve that precisely controls the flow of refrigerant into the evaporator, using electronic sensors and algorithms for greater accuracy compared to traditional mechanical expansion valves. This helps improve system efficiency and performance.

Energy Efficiency: The ratio of useful heating or cooling output to the total energy input in a system. Energy efficiency measures how effectively an HVAC system converts energy into conditioned air, with higher efficiency resulting in lower energy consumption and costs. It is often represented by ratings like SEER or HSPF.

Energy Recovery Ventilator (ERV): A device used in HVAC systems to exchange stale indoor air with fresh outdoor air while transferring heat and moisture between the air streams. This process helps reduce energy consumption by pre-conditioning incoming air, improving both air quality and system efficiency.

Energy Reuse Effectiveness (ERE): A metric used to measure how efficiently energy is reused in a data center or other building, often in relation to heat recovery from HVAC systems. A higher ERE indicates more effective energy reuse.

Energy Reuse Factor (ERF): A measure of how much energy, such as heat from an HVAC system, is reused within a facility instead of being expelled to the environment. The ERF helps assess the sustainability and efficiency of a building’s energy management.

Energy Star®: A program run by the U.S. Environmental Protection Agency (EPA) that certifies products and buildings for energy efficiency. HVAC systems with the Energy Star label meet strict energy efficiency guidelines, helping consumers save on energy costs.

Enthalpy: In HVAC, enthalpy refers to the total heat content of air, which includes both sensible heat (temperature) and latent heat (moisture). Enthalpy is used in calculations for designing HVAC systems that maintain comfort and energy efficiency.

Entropy: A measure of the disorder or randomness in a system. In HVAC, it is related to the efficiency of energy transfer processes, with higher entropy indicating more energy loss or inefficiency.

Evaporating temperature: The temperature at which the refrigerant evaporates in the evaporator coil. This temperature is critical for the cooling process, as the refrigerant absorbs heat from the indoor air, cooling the space.

Evaporator Coil: A key component in air conditioning and refrigeration systems, the evaporator coil absorbs heat from indoor air as refrigerant evaporates within the coil. This cooled air is then circulated back into the building.

Expansion Valve: A device that controls the flow of refrigerant into the evaporator coil, regulating pressure and temperature for optimal cooling performance.

F

Fahrenheit: A temperature scale where water freezes at 32°F and boils at 212°F under standard atmospheric conditions. It is commonly used in the United States for HVAC temperature settings.

Fan: A device used to move air through an HVAC system, aiding in ventilation, cooling, or heating. Fans are essential for circulating conditioned air throughout a building.

Fan coil unit: A small air-handling unit that contains a fan and a coil (either heating or cooling). It circulates air to control the temperature of individual spaces, typically in multi-room buildings.

Filter: A component of the HVAC system that removes dust, debris, and contaminants from the air before it circulates through the system. Clean filters are crucial for maintaining indoor air quality and system efficiency.

Filter-Drier: A component in HVAC systems that removes moisture and contaminants from the refrigerant, ensuring smooth operation and extending the lifespan of the system.

Flue: A duct or pipe that vents combustion gases from a furnace or other heating system to the outside. Proper flue installation is essential for safely removing harmful gases like carbon monoxide.

Fluorocarbon: A type of refrigerant once commonly used in HVAC systems. Fluorocarbons, including CFCs and HCFCs, have been phased out in many countries due to their ozone-depleting properties.

Footprint: In the context of HVAC, this refers to the physical space that a system occupies, as well as its environmental impact, such as carbon footprint or energy consumption.

Free Cooling: A method of cooling that uses outside air, water, or natural resources instead of mechanical refrigeration. Free cooling is often used in data centers and commercial buildings to reduce energy consumption.

Furnace: A heating unit that uses fuel (such as natural gas, oil, or electricity) to generate heat and distribute it throughout a building via ducts or air handlers.

Fuse: A safety device that protects HVAC electrical circuits by breaking the circuit when excessive current flows, preventing damage to components like motors and fans.

F-Gas: Fluorinated gases used as refrigerants in HVAC systems. F-gases are powerful greenhouse gases, and their use is regulated to minimize environmental impact.

F-Gas regulation: Legislation, especially in the EU, that governs the use, containment, and recovery of fluorinated gases to reduce greenhouse gas emissions and protect the environment.

HVAC Terms G – L

G

GAMA (Gas Appliance Manufacturers Association): A former trade association for manufacturers of gas-fired appliances and equipment, which helped set industry standards and guidelines. It is now part of the Air-Conditioning, Heating, and Refrigeration Institute (AHRI).

Gauge pressure: The pressure of a system measured relative to atmospheric pressure. In HVAC, it is often used to measure refrigerant pressure within a system, excluding atmospheric pressure from the calculation.

Geothermal HVAC system: A system that uses the stable temperature of the earth to heat or cool a building. Geothermal systems utilize underground pipes to circulate a liquid that absorbs or dissipates heat, depending on the season. These systems are highly efficient and environmentally friendly but can be expensive to install.

Glide: In HVAC, glide refers to the temperature range over which a refrigerant mixture changes from liquid to gas during evaporation or from gas to liquid during condensation. Non-azeotropic refrigerant blends exhibit glide, which can impact system performance.

Glycol-Cooled System: A cooling system that uses a glycol and water mixture as the cooling medium instead of water alone. Glycol is added to prevent freezing in low temperatures and is used in HVAC systems for chillers or refrigeration in colder environments.

GWP (Global Warming Potential): A measure of how much heat a greenhouse gas traps in the atmosphere compared to carbon dioxide over a specific period. In HVAC, refrigerants with lower GWP are preferred to reduce environmental impact.

H

HCFC (Hydrochlorofluorocarbons): A class of refrigerants that were widely used in HVAC systems but are being phased out due to their ozone-depleting properties. While less harmful than CFCs, HCFCs still contribute to ozone layer depletion and have been replaced with more environmentally friendly alternatives.

Head Pressure: The pressure exerted by the refrigerant as it exits the compressor in an HVAC system. Proper head pressure is critical for system performance, as excessively high or low pressure can affect efficiency and potentially damage the compressor.

Heat capacity: The amount of heat energy required to raise the temperature of a substance. In HVAC, understanding the heat capacity of air, water, or refrigerants is essential for designing systems that efficiently transfer heat.

Heat Exchanger: A device that transfers heat between two or more fluids without them mixing. In HVAC systems, heat exchangers are used in both heating and cooling applications, such as furnaces, air conditioners, and heat pumps, to transfer heat to or from the air.

Heat Gain: The increase in temperature within a space due to external factors such as sunlight, electrical equipment, or body heat. HVAC systems are designed to manage heat gain to maintain a comfortable indoor environment.

Heating Coil: A coil within an HVAC system that heats air as it passes over the coil. The heat can come from electricity, steam, or hot water. Heating coils are common in both furnaces and heat pumps.

Heat Load Calculation: The process of determining the amount of heating required to maintain a desired indoor temperature. Factors such as the size of the building, insulation, and external weather conditions are considered in heat load calculations, which are essential for selecting appropriately sized HVAC equipment.

Heat Loss: The transfer of heat from inside a building to the outside due to factors like poor insulation, windows, or gaps in the building’s structure. Reducing heat loss is a key goal in HVAC design to improve energy efficiency.

Heat Pump: A device that can both heat and cool a space by transferring heat between the indoors and outdoors. In heating mode, it extracts heat from the outside air or ground and transfers it indoors. In cooling mode, it reverses the process to expel heat from the building.

Heat Pump System: A system that provides both heating and cooling by transferring heat between the indoors and outdoors. Heat pumps are energy-efficient and can work in reverse to cool a building in the summer and heat it in the winter.

Heat Transfer: The movement of heat from one substance or location to another. In HVAC systems, heat transfer occurs through conduction, convection, and radiation, allowing for the heating or cooling of spaces.

Hemi-anechoic chamber: A specialized room designed to absorb sound reflections from all directions except the floor. It is often used in HVAC to measure sound emissions from equipment like fans and compressors, ensuring noise control and compliance with standards.

HFC (Hydrofluorocarbon): A type of refrigerant that does not deplete the ozone layer but has a high global warming potential (GWP). HFCs have been used to replace HCFCs but are now being phased out in favor of refrigerants with lower GWP.

HFO (Hydrofluoroolefin): A new class of refrigerants with low global warming potential, used in HVAC systems as an alternative to HFCs. HFOs are more environmentally friendly and are becoming more common in new HVAC installations.

High Performance Computing (HPC): Refers to the use of supercomputers and high-performance computing clusters to solve complex problems. In HVAC, HPC environments require specialized cooling systems to manage the heat generated by powerful processors.

Hot aisle: In data centers, the hot aisle is the space between rows of server racks where hot air from the servers is expelled. HVAC systems in data centers are designed to manage hot and cold aisles to optimize cooling efficiency.

HSPF (Heating Seasonal Performance Factor): A measure of a heat pump’s heating efficiency over an entire heating season. It is calculated by dividing the total heating output (in BTUs) by the total energy consumed (in watts). Higher HSPF ratings indicate better efficiency.

Humidification: The process of adding moisture to the air to maintain desired humidity levels in a building. Proper humidification is important for comfort, health, and protecting building materials.

Humidifier: A device that adds moisture to the air in a space to maintain or increase humidity levels, often used in HVAC systems to improve indoor air quality during dry conditions.

Humidistat: A device that measures and controls the humidity level in a space, similar to how a thermostat controls temperature. It is often used in conjunction with a humidifier or dehumidifier.

Humidity: The amount of water vapor present in the air. In HVAC, controlling humidity is important for maintaining indoor comfort and air quality, as well as preventing issues like mold growth or dry air.

HVAC (Heating, Ventilation, and Air Conditioning): Refers to the systems used to regulate the temperature, humidity, and air quality within a building. HVAC systems provide heating, cooling, and ventilation to maintain comfortable and healthy indoor environments.

Hybrid system (Dual fuel system): A type of HVAC system that combines an electric heat pump with a gas furnace. In mild weather, the heat pump is used for energy-efficient heating and cooling. When temperatures drop and more heating is needed, the system switches to the gas furnace for more powerful heating. Hybrid systems are designed to optimize energy use.

Hydrocarbon refrigerant (HC): A type of natural refrigerant, such as propane or isobutane, that has low global warming potential and no ozone depletion potential. Hydrocarbon refrigerants are becoming more popular in HVAC systems due to their environmental benefits.

I

Ignition: In HVAC systems, ignition refers to the process of starting the combustion of fuel in a furnace or boiler. It can be achieved using different methods, such as a pilot light, hot surface ignition, or electronic spark ignition, to heat the air that is distributed through the building.

Interconnection Agreement: In the context of energy and HVAC systems, an interconnection agreement is a contract between a power producer (such as a building with its own HVAC or energy generation systems) and a utility company. It governs how the energy produced on-site (e.g., solar power) can be connected to the grid and specifies terms for power exchange.

Internet Service Provider (ISP): While not directly related to HVAC, an ISP provides access to the internet. In smart HVAC systems, reliable internet service is necessary for remote control, monitoring, and automation of HVAC functions, making an ISP important for modern systems.

Inverter Compressor: A type of compressor in HVAC systems that adjusts its speed to match the heating or cooling demand, unlike traditional compressors that operate at a constant speed. Inverter compressors improve energy efficiency and provide more precise temperature control, as they can modulate their output based on real-time needs.

K

Kilowatt (kW): A unit of power equivalent to 1,000 watts. In HVAC, kilowatts are used to measure the electrical power consumed by heating and cooling systems. For example, the power consumption of air conditioners, heat pumps, or furnaces is often expressed in kilowatts, which directly impacts energy efficiency and operational costs.

Kyoto Protocol: An international treaty that was adopted in 1997 and came into force in 2005, with the goal of reducing greenhouse gas emissions to mitigate climate change. The Kyoto Protocol has influenced HVAC practices by encouraging the phase-out of refrigerants with high global warming potential (GWP) and promoting more energy-efficient HVAC systems.

L

Latent Cooling Capacity: The energy required to add or remove moisture from the air during the air conditioning process without changing the air temperature. It measures the system’s ability to manage humidity, expressed in terms of the moisture content of the air, typically kg/kg of dry air.

Latent Heat: The energy absorbed or released by a substance during a phase change, such as from liquid to vapor (evaporation) or vapor to liquid (condensation), without a temperature change. This is crucial in HVAC systems for processes like condensation in cooling coils or evaporation in the refrigeration cycle.

Load Calculation: A detailed assessment of a building’s heating and cooling needs based on factors like insulation, window placement, occupancy, and local climate. Load calculations ensure the HVAC system is properly sized for optimal comfort and energy efficiency.

Low Pressure Stage: The portion of an HVAC system, specifically in the refrigeration cycle, where the refrigerant is at its lowest pressure. It generally occurs between the outlet of the expansion valve and the suction inlet of the compressor. In multi-stage systems, this is where the system achieves its coldest temperature.

HVAC Terms M – R

M

Make-Up Air Unit (MUA): A type of HVAC system that supplies fresh, outside air to a building to “make up” for air that has been exhausted. MUAs are typically used in spaces with high ventilation needs, such as commercial kitchens, where indoor air is continually expelled through exhaust systems. They help maintain indoor air quality and balance air pressure within the building.

Manufacturer Approved System: A system or combination of HVAC components that have been tested and certified by the manufacturer to meet certain performance and compatibility standards. For example, using approved systems ensures that a furnace and air conditioner will work together efficiently and comply with industry certifications like those from AHRI (Air-Conditioning, Heating, and Refrigeration Institute).

Media: In the context of HVAC, media refers to the material used in air filters that traps contaminants like dust, pollen, and particulates from the air. Filter media can be made from various materials, such as fiberglass, pleated paper, or synthetic fibers, and its efficiency is often measured using the MERV (Minimum Efficiency Reporting Value) rating system.

Microchannel Coil: A type of condenser coil design used in HVAC systems that consists of small, flat tubes with multiple microchannels, which increase the surface area for heat transfer. Microchannel coils are more efficient, lighter, and require less refrigerant than traditional round-tube coils, making them increasingly popular in modern HVAC equipment.

Mineral Oil: A type of lubricant used in older HVAC systems that utilize chlorofluorocarbon (CFC) and hydrochlorofluorocarbon (HCFC) refrigerants. Mineral oil helps keep moving parts lubricated and ensures smooth operation. However, it has been largely replaced by synthetic oils in newer systems that use more environmentally friendly refrigerants like hydrofluorocarbons (HFCs).

N

N+1: A redundancy design strategy used in HVAC systems, particularly in critical environments like data centers. N+1 means having at least one backup unit for every essential system or component. For example, if a building requires five air conditioning units to maintain the proper temperature, an N+1 system would have six units, ensuring continuous operation even if one unit fails.

NATE (North American Technician Excellence): The leading certification organization for HVAC technicians in the United States. NATE certifies technicians who have passed specialized tests, proving their knowledge and expertise in installing and servicing HVAC systems. It is widely recognized as a benchmark of skill in the HVAC industry.

Natural Refrigerant: A refrigerant that occurs naturally in the environment, such as ammonia (NH3), carbon dioxide (CO2), or hydrocarbons (like propane or isobutane). Natural refrigerants have low global warming potential (GWP) and no ozone depletion potential, making them an environmentally friendly alternative to synthetic refrigerants like HFCs.

Near Azeotrope: A blend of refrigerants that behaves almost like an azeotropic mixture, meaning it has a slight temperature glide during phase changes (evaporation or condensation), but the glide is minimal. These refrigerants are designed for systems where maintaining a near-constant composition of refrigerant is important for system efficiency and reliability.

NEC (National Electrical Code): A set of safety guidelines published by the National Fire Protection Association (NFPA) that standardizes the safe installation of electrical wiring and equipment in the U.S. HVAC technicians must follow NEC regulations when installing or maintaining electrical components in heating and cooling systems to ensure safety and compliance.

NEMA (National Electrical Manufacturers Association): A trade organization that develops standards for electrical products and equipment. In HVAC, NEMA standards define performance criteria for motors, wiring, and electrical enclosures, ensuring compatibility and safety in HVAC installations.

Non-Condensable Gas: A gas that does not condense under the conditions typically used in HVAC systems. In refrigerant systems, non-condensable gases (such as air or nitrogen) can cause problems by reducing system efficiency, increasing pressure, and leading to higher operating temperatures. Proper evacuation of these gases is essential for optimal HVAC performance.

O

ODP (Ozone Depletion Potential): A numerical value assigned to refrigerants and other chemicals that indicates their potential to deplete the ozone layer compared to a reference substance, usually CFC-11 (with an ODP of 1.0). Refrigerants with a high ODP, such as CFCs and HCFCs, are being phased out in favor of those with a low or zero ODP, to comply with environmental regulations like the Montreal Protocol.

Oil Separator: A device used in HVAC and refrigeration systems to remove oil from the refrigerant as it circulates through the system. This helps return the oil to the compressor for lubrication and ensures that the refrigerant remains as pure as possible, improving system efficiency and preventing potential damage.

Orifice: A small, precisely sized opening in an HVAC or refrigeration system that regulates the flow of refrigerant into the evaporator. Orifices control the refrigerant’s pressure and temperature, playing a crucial role in the refrigeration cycle to ensure proper cooling performance.

P

Package Unit (Packaged Unit): A self-contained HVAC system where all components (compressor, condenser, evaporator, and air handler) are housed in a single unit. These units are typically installed outside, either on the roof or next to the building, and are common in commercial applications or homes without basements.

Particulates: Tiny solid or liquid particles suspended in the air, such as dust, pollen, and smoke. In HVAC systems, air filters are used to remove particulates to improve indoor air quality and protect the system from damage caused by debris.

Plenum: An air distribution box in HVAC systems that connects the ductwork to the air handler or furnace. Plenums are used to manage airflow between different parts of the system, ensuring proper air circulation throughout the building.

Precision Air Conditioning (PAC): A specialized air conditioning system designed to maintain very tight temperature and humidity controls. PAC systems are often used in data centers, server rooms, and laboratories where sensitive equipment requires precise environmental conditions.

Pressure and Strength Tests: Tests conducted on HVAC components, such as piping and equipment, to ensure they can withstand operational pressures without failure. These tests are essential for safety and compliance with industry standards, verifying the integrity of the system under various conditions.

Programmable Thermostat: A thermostat that allows users to set different temperatures for different times of the day or week. This helps improve energy efficiency by automatically adjusting the heating or cooling output based on occupancy patterns or time schedules.

PSI (Pounds per Square Inch): A unit of pressure measurement used in HVAC systems to indicate the pressure of refrigerants, air, or other fluids. PSI is commonly used when testing the pressure levels in a system to ensure it is operating within the correct range.

PSIA (Pounds per Square Inch Absolute): A measure of pressure that includes atmospheric pressure (14.7 psi at sea level). PSIA is used to measure absolute pressure, which is important when working with vacuum systems or calculating the total pressure on a system.

PSIG (Pounds per Square Inch Gauge): A pressure measurement that excludes atmospheric pressure, indicating the pressure above ambient conditions. PSIG is often used in HVAC systems to measure refrigerant pressures or air pressure within ducts.

Psychrometric: Refers to the study of the thermodynamic properties of moist air, including temperature, humidity, and pressure. Psychrometric analysis is crucial in HVAC design for controlling indoor air quality and comfort levels.

Psychrometric Chart: A graphical representation of the relationships between air temperature, moisture content (humidity), and other properties of moist air. HVAC professionals use this chart to design and troubleshoot systems for effective temperature and humidity control.

PUE (Power Usage Effectiveness): A metric used to determine the energy efficiency of data centers by comparing the total facility energy usage to the energy used by the IT equipment. HVAC systems in data centers play a critical role in minimizing PUE by optimizing cooling efficiency.

PVC (Polyvinyl Chloride): A type of plastic used in piping for HVAC systems, particularly in ventilation, drainage, and exhaust applications. PVC pipes are durable, lightweight, and resistant to corrosion, making them ideal for HVAC installations.

Q

Q: In the context of HVAC, “Q” usually represents the amount of heat transfer in energy calculations. It is often used in heat load or cooling load calculations to determine the amount of heat added or removed from a space.

R

Rack: In refrigeration systems, a rack is a collection of compressors used to cool large commercial systems. The rack setup allows multiple compressors to work together, providing greater efficiency and redundancy in large refrigeration applications.

Radiant Floor: A type of heating system that warms a room by circulating hot water or electricity through tubes or cables installed beneath the floor. The heat radiates upwards, providing uniform warmth throughout the space, offering an energy-efficient and comfortable heating method.

Radiation: In HVAC, radiation refers to the transfer of heat through electromagnetic waves. Radiant heating systems, like radiant floors or infrared heaters, rely on this principle to transfer heat directly to objects or people without warming the surrounding air.

Reciprocating Compressor: A type of compressor used in HVAC and refrigeration systems that uses a piston driven by a crankshaft to compress refrigerant. It is commonly found in residential and small commercial HVAC systems.

Reclaim: The process of recovering refrigerant from an HVAC system and cleaning it to remove impurities before reusing it in another system. Reclaimed refrigerant meets specific purity standards and can help reduce the use of new refrigerants.

Recovery: The act of removing refrigerant from an HVAC system so it can be reused or disposed of safely. Recovery is essential for preventing the release of harmful refrigerants into the atmosphere.

Recycle: The process of cleaning refrigerant removed from an HVAC system to make it suitable for reuse. Recycling typically involves removing contaminants such as oil and moisture from the refrigerant, but it may not meet the same purity standards as reclaiming.

Refrigerant: A chemical compound used in HVAC systems to absorb and transfer heat as it changes between liquid and gas states in the refrigeration cycle. Common refrigerants include R22, R410A, and newer, more environmentally friendly options like R1234ze.

Refrigerant Charge: The amount of refrigerant that an HVAC system requires for proper operation. Having the correct refrigerant charge is essential for the system to run efficiently and prevent damage to components. (Duplicate removed)

Refrigeration Cycle (Vapour Compression Cycle): The process used in HVAC systems to cool indoor air. It involves four stages: compression, condensation, expansion, and evaporation. The refrigerant absorbs heat from the indoor air, carries it outside, and expels it.

Relative Humidity (%rh): A measure of how much moisture is in the air compared to the maximum amount the air can hold at a given temperature. Expressed as a percentage, relative humidity impacts comfort and HVAC efficiency.

Remote Electronic Expansion Valve (REEV): A type of expansion valve used in HVAC systems that is controlled electronically, allowing for precise regulation of refrigerant flow. This improves system efficiency and response to changes in cooling demand.

Retrofit: The process of upgrading or modifying an existing HVAC system with new components or technologies to improve its efficiency or performance. Retrofitting is often used to modernize older systems without fully replacing them.

R1234ze (HFO Refrigerant): A hydrofluoroolefin (HFO) refrigerant with a very low global warming potential (GWP). It is commonly used as a replacement for older refrigerants like R134a in commercial and industrial HVAC applications.

R134a (HFC Refrigerant): A hydrofluorocarbon (HFC) refrigerant used in various refrigeration and air conditioning applications. R134a has been widely used but is being phased out in favor of refrigerants with lower global warming potential.

R22 (HCFC Refrigerant): A hydrochlorofluorocarbon (HCFC) refrigerant that was once commonly used in air conditioners and refrigeration systems. It is being phased out due to its ozone-depleting properties under the Montreal Protocol.

R407C (HFC Refrigerant): A hydrofluorocarbon (HFC) refrigerant commonly used as a replacement for R22 in air conditioning and heat pump systems. It has lower ozone-depleting potential but is being phased out in favor of refrigerants with lower GWP.

R410A (HFC Refrigerant): A hydrofluorocarbon (HFC) refrigerant widely used in modern air conditioning and heat pump systems. It has no ozone depletion potential but is being phased out due to its relatively high global warming potential.

RCI (HI) and RCI (LO): Terms referring to “Return Chilled Water Temperature Indication High” (HI) and “Return Chilled Water Temperature Indication Low” (LO). These are indicators used to monitor the temperature of return water in chilled water systems.

R-number: A designation used to classify refrigerants, typically consisting of the letter “R” followed by a number (e.g., R22, R410A). The number indicates the type and chemical makeup of the refrigerant, helping professionals identify the appropriate refrigerant for specific HVAC applications.

Read more about HVAC:

- HVAC Industry Trends and Outlook for 2025

- HVAC Tools and Equipment: 56 Things Your Business Needs

- HVAC Installer Job Description: Skills, Background, and More (w/ Job Post Template!)

- HVAC Training: The Best Courses and Schools for HVAC Careers

- The 7 Best HVAC Software Solutions for 2024

- HVAC Technician Job Description: Skills, Background, and More (w/ Job Post Template!)

- 75+ HVAC Facts and Statistics You Need to Know in 2025 (w/ Infographic!)

HVAC Terms S – Z

S

Screw Compressor: A type of compressor used in large commercial HVAC and refrigeration systems. It uses two helical rotors to compress refrigerant, providing efficient, continuous operation with minimal noise.

Scroll Compressor: A type of compressor commonly used in air conditioning and heat pump systems. It uses two spiral-shaped scrolls to compress refrigerant, making it more efficient and quieter than traditional reciprocating compressors. Scroll compressors are known for their durability and energy efficiency.

SEER (Seasonal Energy Efficiency Ratio): A measure of the cooling efficiency of an air conditioner or heat pump over an entire cooling season. It is calculated by dividing the system’s cooling output by the total energy consumed in watt-hours. Higher SEER ratings indicate more efficient systems.

Self-contained System: An HVAC system in which all components, such as the compressor, condenser, and evaporator, are housed in a single unit. These systems are often used in small spaces or buildings where space for external components is limited.

Sensible Cooling Capacity: The amount of heat that an air conditioning system can remove from the air without changing the moisture content. Sensible cooling refers to temperature reduction only, not to the removal of humidity.

Sensible Heat: The heat energy that causes a change in temperature in a substance, but not a change in its state (e.g., from liquid to gas). In HVAC, sensible heat is the heat removed or added that directly affects the air temperature.

Sensible Heat Ratio (SHR): The ratio of sensible heat to total heat (which includes both sensible and latent heat). In HVAC, it’s a measure of how much of the cooling effect is due to temperature reduction versus humidity control. A higher SHR means more cooling is being used to lower temperature rather than humidity.

Sensor: A device that detects physical changes such as temperature, humidity, or pressure, and sends signals to an HVAC system to adjust settings accordingly. Common sensors in HVAC systems include temperature sensors, humidity sensors, and pressure sensors.

Server: In the context of HVAC, particularly in data centers, a server is a piece of IT equipment that generates significant heat. Cooling systems in data centers must manage the heat produced by servers to prevent overheating and ensure efficient operation.

Single-Speed: Refers to an HVAC system where the compressor operates at a constant speed. These systems run at full capacity when turned on, as opposed to variable-speed systems that can adjust output based on demand.

Split System: An HVAC system where the components are divided between indoor and outdoor units. The indoor unit typically contains the evaporator and air handler, while the outdoor unit houses the compressor and condenser. Split systems are common in both residential and commercial buildings.

Subcooling: The process of cooling refrigerant below its condensation temperature after it has condensed into a liquid. Subcooling improves the efficiency of the refrigeration cycle by ensuring that only liquid refrigerant enters the expansion valve.

Superheating: The process of heating refrigerant vapor above its boiling point after it has evaporated. Superheating ensures that no liquid refrigerant reaches the compressor, protecting it from damage and improving system efficiency.

By ensuring that only refrigerant vapor, and not liquid, reaches the compressor, superheating prevents a condition known as “liquid floodback,” which can severely damage the compressor. Additionally, maintaining the right level of superheat enhances heat exchange efficiency, as the vapor refrigerant absorbs more heat from the surroundings in the evaporator.

T

Tab (Test, Adjust, Balance): A procedure in HVAC commissioning where air distribution systems are tested and adjusted to ensure that air is properly balanced across different zones. TAB ensures that each space receives the correct amount of conditioned air for comfort and efficiency.

Thermostat: A device that senses the temperature of a space and controls the HVAC system to maintain the desired temperature. It signals the system to turn on or off based on the set point. Modern thermostats can be programmable or smart, allowing for remote control and energy-efficient scheduling.

Thermostatic Expansion Valve (TXV): A valve in HVAC systems that regulates the flow of refrigerant into the evaporator based on the cooling demand. It adjusts refrigerant flow by sensing superheat, ensuring optimal efficiency and preventing liquid refrigerant from entering the compressor.

Thyristor: A semiconductor device used in HVAC systems to control high-power equipment like compressors or heating elements. Thyristors allow precise control of electrical power, making them useful in systems requiring variable speed or power control, such as inverters or heating units.

Ton: A unit of measure used to describe the cooling capacity of an air conditioning system. One ton of cooling is equal to 12,000 BTUs per hour. This term originates from the amount of heat needed to melt one ton of ice in 24 hours.

Turning Vane: A metal component installed inside ductwork to guide air efficiently around corners or bends. Turning vanes reduce air turbulence and pressure loss in the ducts, improving overall airflow and system efficiency.

Two-Speed: Refers to HVAC systems with two operating speeds—low and high. These systems adjust their output to meet varying cooling or heating demands, improving energy efficiency compared to single-speed systems that run at full capacity.

U

Upflow Furnace: A type of furnace where air enters from the bottom and is heated as it passes through the furnace, before being discharged upwards into the ductwork. Upflow furnaces are commonly used in homes with duct systems located in the ceiling or attic, where the heated air naturally rises to be distributed throughout the space.

Upflow Unit: An HVAC system configuration where the airflow is directed upward, typically used in situations where the ductwork is located above the unit, such as in basements or utility rooms. It refers to both furnaces and air conditioners that discharge conditioned air upward for distribution through the ducts.

UPS (Uninterruptible Power Supply): A device that provides backup power to HVAC control systems and other critical equipment in case of power outages. UPS systems are essential for maintaining continuous operation in environments like data centers, hospitals, or commercial buildings, where even short power interruptions can cause disruptions or damage to sensitive systems.

Boost HVAC techs’ productivity with Workyard’s precise time clock

See How it Works

V

Vacuum: In HVAC, a vacuum refers to the removal of air and non-condensable gases from a refrigeration or air conditioning system. Creating a vacuum is essential before charging the system with refrigerant to prevent contaminants from affecting performance and causing damage.

Vacuum Test: A process used in HVAC systems to ensure that all air, moisture, and contaminants have been removed before refrigerant is added. This is critical for the efficient operation of refrigeration and air conditioning systems, as the presence of moisture or air can reduce system performance and lead to failures.

Vapor: The gaseous form of a substance that is normally liquid or solid at room temperature. In HVAC, the term often refers to the refrigerant in its gaseous state as it moves through the system, absorbing or releasing heat.

Vapor Barrier/Seal: A material or membrane used in building construction and HVAC to prevent moisture from passing through walls, ceilings, or floors. Vapor barriers are essential for preventing condensation, mold, and structural damage by controlling the movement of water vapor through building envelopes.

Variable Speed Motor: An HVAC motor that can operate at varying speeds depending on the system’s heating or cooling demand. Variable-speed motors improve energy efficiency, reduce noise, and offer more precise control of indoor temperature compared to single-speed motors.

Variable-Speed: Refers to HVAC systems with a motor or compressor that can operate at different speeds, adjusting the system’s output based on demand. Variable-speed systems are more energy-efficient and provide better temperature control compared to single-speed or two-speed systems, as they can ramp up or down based on real-time cooling or heating needs.

Ventilation: The process of supplying fresh air to an indoor space while removing stale or contaminated air. Ventilation systems are critical for maintaining indoor air quality and comfort, and they are often integrated with HVAC systems to regulate airflow and temperature.

Vents: Openings in the HVAC system through which air is delivered to and removed from different rooms in a building. Supply vents deliver conditioned air, while return vents draw air back into the system for reconditioning.

Volt: A unit of electric potential or electromotive force. In HVAC systems, voltage is used to measure the electrical energy supplied to components like motors, compressors, and fans. Ensuring the correct voltage is essential for the safe and efficient operation of HVAC equipment.

Voltage: The difference in electric potential between two points. Voltage drives the current that powers electrical components in HVAC systems, such as compressors, fans, and control systems.

W

Water Column (WC): A unit of pressure measurement used in HVAC systems, particularly for measuring gas pressure or airflow in ducts. Water column refers to the height of a column of water that would produce the equivalent pressure, often measured in inches (in. WC). It’s commonly used when measuring gas pressure in furnaces and boilers.

Water Usage Effectiveness (WUE): A metric used to measure the efficiency of water use in data centers and other facilities, especially in relation to cooling. It is calculated by dividing the total water used by the IT equipment’s energy usage. WUE helps assess the sustainability of water consumption in cooling systems, promoting efficient use of water resources.

Water-Cooled System: An HVAC system that uses water as the cooling medium instead of air. Water-cooled systems are more efficient than air-cooled systems for large-scale applications, such as in industrial or commercial buildings, where water absorbs and transfers heat more effectively. These systems typically use cooling towers to dissipate heat from the water.

Watt: A unit of power that measures the rate of energy transfer or consumption. In HVAC, watts are used to quantify the electrical power consumed by components such as fans, compressors, and heaters. One watt equals one joule of energy per second, and electrical devices are typically rated by their wattage to indicate their energy usage.

Wet Bulb Temperature: The lowest temperature that can be reached by evaporating water into the air. It is measured using a wet bulb thermometer and is important in HVAC for assessing the cooling capacity of evaporative cooling systems, as well as for calculating relative humidity.

Wet Bulb Thermometer: A thermometer used in combination with a dry bulb thermometer to measure wet bulb temperature. It has a cloth-covered bulb that is moistened and exposed to airflow, allowing the temperature reading to reflect the cooling effect of evaporation. Wet bulb readings are critical in psychrometric calculations for determining humidity and comfort levels.

Z

Zeotrope: A refrigerant mixture composed of two or more substances with different boiling points. Unlike azeotropic mixtures, zeotropes exhibit a temperature glide during phase changes (evaporation and condensation), meaning that the components do not evaporate or condense at a constant temperature. Zeotropes are used in HVAC systems where specific performance characteristics, such as better efficiency or environmental compliance, are desired.

Zoning: In HVAC, zoning refers to dividing a building into separate areas (zones) that can be heated or cooled independently. Each zone has its own thermostat and damper control, allowing for customized temperature control. Zoning improves comfort and energy efficiency by enabling different temperatures in different parts of a building based on occupancy or use.

Wrapping Up

It takes time to learn HVAC terms; technicians will learn more as they take on complex jobs in the field.

But the rewards of learning make all the difference in earning customers’ trust. Knowledgeable technicians can clearly answer any question, putting them in the best position to drive more repeat customers to your business.

As your business grows, you can help free up time on your team’s busy schedules by investing in HVAC software that automates tedious administrative tasks.

Workyard does this by simplifying time tracking, job scheduling, and task management all from the same app. With Workyard, your HVAC technicians can spend fewer hours doing paperwork and more time investing in their HVAC training or going the extra mile for your clients.

Discover how Workyard can help your team save hours (and money) while in the field, or try it free today to see how it works.

Energy efficiency in HVAC terms refers to how effectively a heating, ventilation, and air conditioning system converts energy (such as electricity or fuel) into heating or cooling output. Common energy efficiency ratings include SEER (Seasonal Energy Efficiency Ratio) for cooling systems and AFUE (Annual Fuel Utilization Efficiency) for furnaces. Systems with higher SEER or AFUE ratings consume less energy to produce the same heating or cooling effect, reducing energy bills and minimizing environmental impact. Modern energy-efficient HVAC systems can cut energy use by up to 30% compared to older models, making them a critical factor for reducing operational costs for homeowners and businesses alike.

In HVAC terms, WC stands for Water Column, a unit of pressure measurement used primarily in gas piping and ventilation. Water column (often expressed as inches WC or in. WC) measures the pressure that a column of water would exert. For example, in gas furnaces, proper gas pressure is critical for efficient combustion, and technicians measure this pressure in inches of WC. Typically, natural gas furnaces operate at around 3.5 inches WC, while propane furnaces run at about 11 inches WC. Understanding WC is important for ensuring safe and efficient HVAC system operation.

In HVAC terms, a consumable refers to any part or material that gets used up or needs regular replacement to ensure the system runs efficiently. Common HVAC consumables include air filters, refrigerants, and lubricants. For example, air filters must be replaced periodically to maintain proper airflow and air quality in a system, while refrigerants may need to be topped off or replaced if a leak occurs. Regular maintenance of consumables is essential for preventing system failures and ensuring the longevity and efficiency of the HVAC system.

In HVAC terms, TAB stands for Testing, Adjusting, and Balancing. This is a process performed to ensure that the HVAC system’s airflow, water flow, and temperature distribution are optimized for performance. TAB is especially important in large commercial buildings where uneven heating or cooling can occur. By testing, adjusting, and balancing the system, technicians make sure every room receives the correct amount of conditioned air. TAB improves energy efficiency, enhances comfort, and prevents unnecessary wear and tear on the HVAC system components.

For HVAC technicians and business owners, some key HVAC terms include:

- SEER (Seasonal Energy Efficiency Ratio): A rating for cooling system efficiency.

- AFUE (Annual Fuel Utilization Efficiency): A furnace’s fuel efficiency rating.

- COP (Coefficient of Performance): Measures the heating efficiency of heat pumps.

- MERV (Minimum Efficiency Reporting Value): Air filter efficiency rating.

- BTU (British Thermal Unit): A unit measuring heating or cooling capacity. Understanding these HVAC terms is essential for choosing the right system and ensuring optimal performance. Each of these terms reflects a different aspect of HVAC system performance, from energy efficiency to heating and cooling capacity.