In the field service and construction business, every piece of equipment, from small tools to heavy machinery, is essential to keep projects on track. Even a tiny oversight can disrupt operations and lead to costly delays or repairs.

This is why equipment inspection checklist templates are simple but powerful tools to ensure safety, prevent equipment breakdowns, reduce downtime, and streamline your overall equipment management.

But if you manage large teams and complex workflows, ensuring all equipment and machinery are inspected and in top condition may not be prioritized enough. Unless you have a standardized and efficient system you can use, like a well-structured equipment inspection checklist template.

Because these templates are preformatted with sections, categories, and step-by-step guides for inspecting and evaluating equipment, they eliminate guesswork and ensure nothing is skipped or missed. You can also customize them for different equipment and vehicles.

Inspection checklist templates help workers and supervisors see potential problems before they become bigger and costlier. They help minimize safety risks and keep your team working efficiently.

In this article, we’ll explore how equipment inspection checklist templates can help maintain a safe and efficient work environment and extend the lifespan of equipment and vehicles.

Templates by Type

- Equipment Inspection Checklist Templates

- Forklift Inspection Checklist Templates

- Forklift Daily Checklist Templates

- Scissor Lift Inspection Checklist Templates

- Truck Inspection Checklist Templates

- Trailer Inspection Checklist Templates

- Crane Inspection Checklist Templates

- Fleet Maintenance Checklist Templates

Equipment Inspection Checklist Templates

Running a construction or field service business can be challenging. You must maintain efficient operations while ensuring the safety of your crew and your equipment. Fortunately, there are tools you can integrate into your workflows and with your routine equipment inspections.

Our Equipment Inspection Checklist Template can help optimize the inspection process by standardizing checklists for each equipment type and setting regular inspection schedules. Identify operational inefficiencies and preventive maintenance needs early to prevent breakdowns and downtime.

How to Get These Templates:

-

PDF

- Click the link

- Click the Download icon in the upper right

-

Microsoft Word (.DOCX) and Excel (.XLSX)

- Click the link

- Open the File menu in the upper right

- Click Download

- Select .docx (Word) or .xlsx (Excel)

-

Google Docs and Sheets:

- Click the link

- You must be logged into a Google Drive account

- Open the File menu in the upper right

- Click Make a Copy

How to Use These Templates:

- Logically Organized: Easy to read and follow with clear instructions.

- Comprehensive Checklist: Get comprehensive, specific inspection points.

- Customization Options: Tailor it for different equipment types and models.

- Standardized Format: Ensure consistency across all inspections.

- Clear Criteria: Have a transparent grading system and include action items.

Forklift Inspection Checklist Templates

Regular forklift inspections are necessary to maintain your business’s operational efficiency and safety. However, this task is not without its share of challenges. For example, more training on inspection procedures or safety standards may be needed. Some operators may rush through inspections, focus only on visible issues, and leave out critical details.

With our free Forklift Inspection Checklist, you can improve your inspection processes and operational efficiency. This easy-to-use and ready-made template helps you identify maintenance needs, safety risks, and regulatory compliance.

How to Get These Templates:

-

PDF

- Click the link

- Click the Download icon in the upper right

-

Microsoft Word (.DOCX) and Excel (.XLSX)

- Click the link

- Open the File menu in the upper right

- Click Download

- Select .docx (Word) or .xlsx (Excel)

-

Google Docs and Sheets:

- Click the link

- You must be logged into a Google Drive account

- Open the File menu in the upper right

- Click Make a Copy

How to Use These Templates:

- Well-Structured Checklist: Inspection items are divided into organized sections.

- Clear and Easy-to-Follow: Be guided by clear and straightforward language and steps.

- Comprehensive Coverage: It includes critical safety and mechanical component checks and operational tests.

- Action Items and Next Steps: Get criteria for inspection items and follow-up actions.

- Digital or Paper Option: Log inspections digitally or print them for manual entries.

Forklift Daily Checklist Templates

Proper forklift checks ensure safe conditions and operations on every shift. Daily forklift inspections help identify and address safety or maintenance issues, ensure the forklift is ready for use, and, ultimately, extend its lifespan.

Our free Forklift Daily Checklist Template enhances a forklift’s operational safety and performance by providing an organized and logical way of checking all its critical components. It also helps forklift operators document minor issues to support maintenance activities.

How to Get These Templates:

-

PDF

- Click the link

- Click the Download icon in the upper right

-

Microsoft Word (.DOCX) and Excel (.XLSX)

- Click the link

- Open the File menu in the upper right

- Click Download

- Select .docx (Word) or .xlsx (Excel)

-

Google Docs and Sheets:

- Click the link

- You must be logged into a Google Drive account

- Open the File menu in the upper right

- Click Make a Copy

How to Use These Templates:

- User-Friendly Layout: Have an easy-to-follow checklist with simple and clear language.

- Critical Components: It provides comprehensive coverage of all critical components of a forklift.

- Customization Options: Customize by forklift model, feature, components, or fuel type.

- Operator Notes: Have a space for comments and findings.

- Easy Sharing: Share via Excel, Word, GDocs, GSheets, or PDF format.

Scissor Lift Inspection Checklist Templates

To ensure worker safety, optimum equipment performance, and regulatory compliance, you must start by ensuring all equipment are safe, ready to use, and well-maintained. Protect your employees from accidents and prevent equipment downtime or damage by ensuring all safety mechanisms of your scissor lift are functional.

This Scissor Lift Inspection Checklist Template can help enhance the safety of your employees, your business operations, and the overall efficiency of your scissor lifts. This easy-to-use and customizable tool can also save you costs through preventative maintenance.

How to Get These Templates:

-

PDF

- Click the link

- Click the Download icon in the upper right

-

Microsoft Word (.DOCX) and Excel (.XLSX)

- Click the link

- Open the File menu in the upper right

- Click Download

- Select .docx (Word) or .xlsx (Excel)

-

Google Docs and Sheets:

- Click the link

- You must be logged into a Google Drive account

- Open the File menu in the upper right

- Click Make a Copy

How to Use These Templates:

- Organized Structure: Streamline your inspection with a clear, easy-to-follow process.

- Comprehensive Checklist: Cover all critical areas and essential components.

- Safety Focus: Give high priority to safety-related components.

- Action Steps: Have clear pass or fail options and indicate the next steps.

- Inspector Accountability: Include operator sign-offs and supervisor review.

Truck Inspection Checklist Templates

A safe, reliable, and well-maintained truck is essential for transportation, logistics, and field service businesses. Regular truck inspections prevent breakdowns, minimize downtime, and improve the overall condition of the trucks. Moreover, they ensure the safety of your drivers and the public and help protect your business from legal liability in case of accidents.

This free Truck Inspection Checklist covers all critical components of truck inspections. It can also be customized for different types of trucks and specialized vehicles.

What you’ll find in this template:

- Clear, Simple Layout: Use an organized checklist with easy-to-understand language.

- Coverage of Key Areas: It includes critical areas of trucks for inspection.

- Safety Priority: Prioritize critical safety features and standards.

- Trip and Route Checks: Conduct pre-, en-route, and post-trip checks.

- Adaptability: Configure the checklist for different types of trucks.

Trailer Inspection Checklist Templates

In the fast-paced and competitive construction and field service industries, you want to ensure every piece of equipment works properly 24/7. Delays and downtimes not only disrupt operations but impact customer satisfaction and profitability.

Our free Trailer Inspection Checklist Template offers many benefits to businesses that rely on trailers for their operations. It’s easy to use and customizable for different trailers, ensuring nothing gets overlooked during trailer inspections.

How to Get These Templates:

-

PDF

- Click the link

- Click the Download icon in the upper right

-

Microsoft Word (.DOCX) and Excel (.XLSX)

- Click the link

- Open the File menu in the upper right

- Click Download

- Select .docx (Word) or .xlsx (Excel)

-

Google Docs and Sheets:

- Click the link

- You must be logged into a Google Drive account

- Open the File menu in the upper right

- Click Make a Copy

How to Use These Templates:

- Easy to Understand: Avoid confusion with a well-structured checklist and simple language.

- Safety Focus: Ensure all crucial safety elements are inspected.

- Industry Regulation Compliance: Align with industry standards and keep records for audits.

- Actionable Items: Give items pass or fail marks and include instructions on the next steps.

- Editable and Shareable: Choose from a digital checklist or a paper version and share in your preferred format.

Crane Inspection Checklist Templates

Businesses that rely heavily on cranes must ensure they function properly to ensure worker safety. A well-maintained crane also reduces the risk of breakdowns and downtimes, saving you money on emergency repairs, parts replacement, or crane rentals. Routine crane inspections also extend the service life of your cranes.

This free Crane Inspection Checklist Template helps ensure the safety and efficiency of your crane operations. Its sections include critical inspection areas and components so crane operators and supervisors will not skip or overlook anything

How to Get These Templates:

-

PDF

- Click the link

- Click the Download icon in the upper right

-

Microsoft Word (.DOCX) and Excel (.XLSX)

- Click the link

- Open the File menu in the upper right

- Click Download

- Select .docx (Word) or .xlsx (Excel)

-

Google Docs and Sheets:

- Click the link

- You must be logged into a Google Drive account

- Open the File menu in the upper right

- Click Make a Copy

How to Use These Templates:

- Organized Layout: It’s simple to use with easy-to-understand language.

- Comprehensive Checklist: It covers vital parts and critical areas for inspection.

- Operation Checks: Inspect before, during, and after crane operations.

- Editable Document: Customize it for different crane types and models.

- Simple Evaluation System: Pass or fail items and provide instructions for anything that fails inspection.

Fleet Maintenance Checklist Templates

Routinely checking your fleet ensures all vehicle safety systems are functioning and safety requirements are met. It not only protects your drivers, but other road users as well by minimizing mechanical failure that may cause accidents. Regular fleet maintenance also promotes a safety-first culture throughout your company.

Our free downloadable Fleet Maintenance Checklist Template helps you conduct maintenance inspections efficiently and thoroughly. With its well-organized structure and detailed sections, no critical component will be skipped or overlooked.

How to Get These Templates:

-

PDF

- Click the link

- Click the Download icon in the upper right

-

Microsoft Word (.DOCX) and Excel (.XLSX)

- Click the link

- Open the File menu in the upper right

- Click Download

- Select .docx (Word) or .xlsx (Excel)

-

Google Docs and Sheets:

- Click the link

- You must be logged into a Google Drive account

- Open the File menu in the upper right

- Click Make a Copy

How to Use These Templates:

- Organized Structure: Follow the step-by-step inspection process in easy-to-understand terms.

- Key Components: It includes critical components for a comprehensive vehicle inspection.

- Safety Focus: Prioritize safety features and mechanisms.

- Customization Option: Use it for various vehicles in your fleet and specialized items.

- Easy Sharing: Share in your preferred format (GDoc, Excel, PDF, etc.).

Manage equipment, worker time, projects, and more with the Workyard app!

See how it works

What are Equipment Inspection Checklist Templates?

Equipment inspection checklist templates are structured documents used to evaluate the condition and safety of various types of equipment, particularly in industries such as construction, manufacturing, and warehousing.

These templates guide operators and maintenance personnel in ensuring necessary checks are performed before equipment is used. They promote safety and operational efficiency and help prevent expensive repairs and parts replacements.

Since many industries must comply with strict safety regulations, regular equipment inspections also become faster and more efficient with a checklist template.

Equipment inspection checklist templates are organized into sections and have a structured format. They include sections for equipment identification, specific inspection items, and notes from inspectors. They can also be customized to specific industry or equipment requirements.

Good Examples of Equipment Inspection Checklist Template Use

Whether in construction or field services, using the right equipment checklist template is a significant first step in ensuring your equipment and vehicles stay in peak condition. Here are some specific examples of how you can effectively use them for different types of machinery to implement these best practices into your operations.

-

Inspecting General Equipment: Use an equipment inspection checklist for bulldozers, generators, or excavators. Cover critical components like safety systems, tire conditions, fluid levels, and structural integrity.

-

Conducting Forklift Inspection Before Every Shift: Warehouse employees can inspect forklifts before the start of their shifts to ensure they are safe to operate and identify potential safety risks, such as brake issues, tire wear, and more.

-

Performing Daily Forklift Safety Check: Forklift operators at manufacturing facilities can complete this checklist for daily checks, such as tire conditions, battery charge, steering functionality, and hydraulic systems.

-

Ensuring Scissor Lifts are Ready for Use: Construction companies using scissor lifts can use this template to check that emergency stops, guardrails, and platform controls are working correctly.

-

Inspecting Trucks Before They Hit the Road: Logistics companies can inspect trucks before they are dispatched to ensure all systems are operational. Key areas to check include engine fluid levels, brake systems, tires, wipers, lights, and reflectors.

A Step-by-Step Guide to Using Equipment Inspection Checklist Templates

Having inspection checklist templates is a great start, but knowing how to use them effectively is just as important. Here’s a step-by-step guide to ensure you use and make the most of these checklist templates.

Step 1: Choose the Right Inspection Checklist Template

Use Case Examples:

- Equipment Inspection Checklist Template: Ideal for inspecting different types of general equipment for construction, warehousing, and manufacturing industries.

- Forklift Inspection Checklist Template: Ideal for routine, safety, and mechanical inspections of forklifts in a construction or warehouse environment.

- Forklift Daily Checklist Template: Best for shift-based or daily forklift operational checks to identify any urgent issues.

- Scissor Lift Inspection Checklist Template: Commonly used for safety and mechanical scissor life inspections in maintenance and construction projects.

- Truck Inspection Checklist Template: Ideal for pre-trip and periodic inspections of commercial trucks used for service delivery, transportation, and logistics.

- Trailer Inspection Checklist Template: Typically used for regular inspections of trailers used with trucks to transport goods over long distances.

- Crane Inspection Checklist Template: Best for safety and mechanical inspections of cranes used in heavy lifting, construction, and shipping.

- Fleet Maintenance Checklist Template: Best for regular and comprehensive inspections and preventive maintenance of an entire fleet of vehicles.

Action: Select the best checklist template by identifying the type of equipment or vehicle, determining the inspection frequency, and the inspection’s purpose.

Step 2: Prepare for the Equipment Inspection

Use Case Examples:

- Equipment Inspection Checklist Template: Gather the tools needed and ensure you can access the equipment. Review previous maintenance logs for any recurring or unresolved issues.

- Forklift Inspection Checklist Template: Ensure the forklift is powered down and parked on a flat, stable surface with the brake engaged. Make sure you have access to the panels and compartments. Review past inspection records to see if there are recurring issues.

- Forklift Daily Checklist Template: If it’s an electric forklift, make sure the battery is adequately charged. Ensure you have access to the forklift panels, components, and systems. Review the operator manual for reference.

- Scissor Lift Inspection Checklist Template: Park the scissor lift in an open area and ensure you have full access to its controls. Wear safety gear like a helmet and a harness. Power down the scissor lift when inspecting tires and hydraulic hoses.

- Truck Inspection Checklist Template: Prepare the inspection tools, such as fluid testers and pressure gauges. Review previous inspection records to see if there are any unresolved issues.

- Trailer Inspection Checklist Template: Make sure the trailer is empty for easy access to the frame, brakes, and tires. Ensure the connection system is disconnected during inspection and properly aligns with the truck when connected.

- Crane Inspection Checklist Template: Power down and secure the crane to prevent accidental movements when inspecting the hoisting mechanisms, hydraulic systems, wire ropes, and hooks. Review the operator manual for the crane’s inspection needs.

- Fleet Maintenance Checklist Template: Review previous vehicle records and maintenance logs to identify overdue service or recurring problems. Have the right tools for different vehicle types in the fleet. Schedule repairs and preventive maintenance based on the inspection findings.

Action: Have your inspection checklist ready and complete it step by step to avoid missing crucial steps.

Step 3: Conduct a Visual Inspection

Use Case Examples:

- Equipment Inspection Checklist Template: Inspect the exteriors, tires, tracks, belts, hoses, and safety labels for signs of damage, rust, or wear and tear. Look for fluid leaks and check the overall structural integrity.

- Forklift Inspection Checklist Template: Check the mast and body for visible damage, dents, cracks, or corrosion. Inspect the forks, attachments, hydraulic hoses, chains, lights, and mirrors.

- Forklift Daily Checklist Template: Conduct an exterior inspection around the forklift. Ensure the tires are free of punctures and properly inflated. Check the battery, fuel system, forks, attachments, controls, and gauges to ensure they work correctly.

- Scissor Lift Inspection Checklist Template: Do a visual inspection of the platform and guardrails, wheels and tires, joysticks and control panel, hydraulic system, chassis and frame, and emergency stop and alarms.

- Truck Inspection Checklist Template: Critical components to inspect visually include the truck’s exterior, tires, lights, reflectors, brakes, suspension, mirrors, windshield, and undercarriage.

- Trailer Inspection Checklist Template: Inspect the coupling devices to ensure the safety chains, kingpin, and fifth wheel are secure and damage-free. Inspect the frame, chassis, tires, axles, lights, and reflectors. Also, check the brakes, suspension, and cargo securement.

- Crane Inspection Checklist Template: Inspect the boom, jib, and extensions for signs of damage. Check the chains and wire ropes, hydraulic hoses, hook, load block, clutch, brake, control systems, and safety devices.

- Fleet Maintenance Checklist Template: Check for damage to the exterior. Look at the tires and wheels, lights and reflectors, brakes and suspension, mirrors, windshield, and windows, and check for fluid leaks underneath.

Action: Follow the inspection checklist template for consistency and to ensure nothing is missed. Check thoroughly and document everything for proper follow-up maintenance or repair.

Step 4: Go Through the Checklist Step by Step

Inspect the items on the vehicle or equipment as they are listed and categorized in the checklist. Typically, the first items are the key components, such as tires, brakes, fluid levels, safety devices, and electrical systems.

For every component inspected, tick pass/fail or satisfactory/unsatisfactory to determine whether it meets safety and operational standards. Make sure no item has been missed or skipped.

Step 5: Document Any Issues or Deficiencies

Note any specific issue or problem on any component that fails the inspection. Attach a photo to the digital checklist or support it with detailed notes and descriptions. Report it to the maintenance teams immediately to schedule repairs or preventive maintenance. Once the inspection is complete, sign off on the checklist and forward it to the manager or supervisor for review and approval.

With this guide, you can use our free inspection checklist templates effectively to improve workplace and equipment safety and ensure the reliability and longevity of your equipment and vehicles.

Your Next Steps After Using Equipment Inspection Checklist Templates

These Equipment Inspection Checklist Templates are helpful in performing routine inspections, logging findings, and addressing any issues identified during inspections. Integrate them into daily operations to prevent frequent machine breakdowns and save money on repairs and replacement parts.

Over time, you can use these checklists’ data to identify trends, boost operational safety and efficiency, and ensure compliance with industry regulations.

Ready to make the most of your Equipment Inspection Checklist Templates? Here’s what we recommend doing next after reading this article…

Download Your Free Equipment Inspection Checklist Templates: Use the templates provided to conduct more organized and efficient inspections of machinery and vehicles.

Evaluate Your Equipment and Vehicle Inspection Needs: As your fleet grows and inspections become more frequent, consider whether a more sophisticated tool might better suit your needs.

These equipment inspection checklist templates offer a simple but structured framework for conducting routine inspections. More importantly, they help maintain equipment safety, prevent breakdowns, and ensure compliance with industry standards without incurring additional costs.

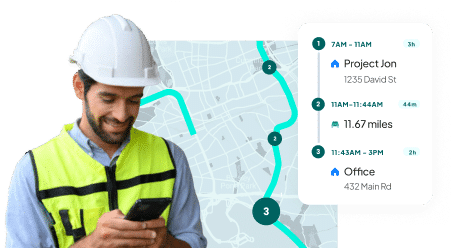

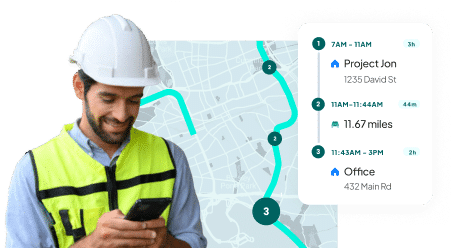

But while free templates are helpful, a more advanced tool like Workyard offers more features, including precise GPS tracking, job scheduling, job monitoring, labor costing, reporting, and integrations with payroll and accounting software.

Workyard streamlines inspections and enhances overall operational efficiency. It allows you to minimize errors and optimize resource allocation, saving time and money.

Upgrading to a platform like Workyard can improve equipment maintenance, productivity, and profitability. Start your free 14-day trial today!

Manage equipment, worker time, projects, and more with the Workyard app!

See how it works

Excel

Excel